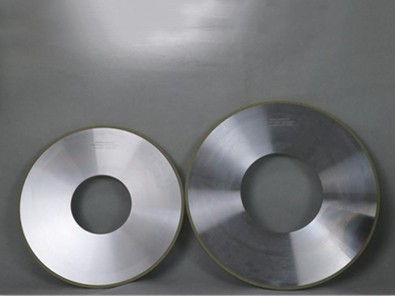

* The First Vitrified Diamond Grinding Wheel used in thermal spraying coating in MoreSuperHard

* Vitrified bond and Resin bond, Vitrified bond has longer lifespan and higher efficiency than resin bond

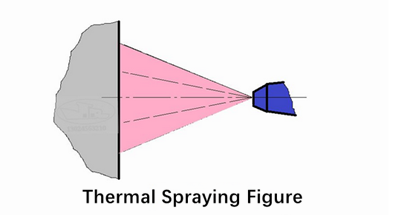

* Used for cylindrical grinding of tungsten carbide coating in thermal spraying industry

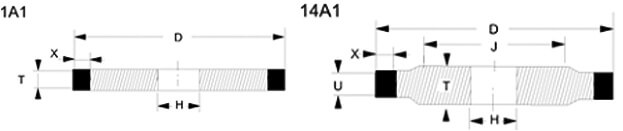

* Models: 1A1(Diameter: 100mm-1200mm), 14A1

Applications:

* For tungsten carbide workpieces

* Steel based tungsten carbide coating workpiece

* Non-metallic materials semi-finishing grinding and finishing grinding, etc.

After constant adjustment of formula and technology

We finally successfully developed the first Vitrified Diamond Grinding Wheel for thermal spraying coating industry

Features:

* The bonding strength of vitrified bond to grinding is better than resin bond

* After customized diamond grinding tools with higher diamond concentration, it is less heat and jam generate in grinding

* High grinding efficiency

* Very sharp grinding

* Long lifespan and easy to dress

In terms of the shaping and dressing of the abrasive tools, it is relatively easy to operate (by using diamond dressing tools, to improve work efficiency and save the time of disassembly of the grinding wheel).

It is generally used for semi-finishing grinding, finishing grinding, and forming grinding with large contact surface, etc.

Therefore, vitrified bond is a kind of bond that is increasingly widely used until now.

Resin Bond Grinding Wheel is also mainly used in thermal spraying coating process

Features:

* Excellent elasticity and polishing effect

* After forming the abrasive tools, it has good self-sharpening

* Less jam and dress, with highly grinding efficiency

* High finishing of work piece

* Low grinding temperature

Specification for Vitrified Bond Diamond Grinding Wheel for thermal spraying coating.

Type | D | X | U |

1A1 | 100 | 5 10 15 20 | 3-12 |

1A1 | 125 | 5 10 15 20 | 3-12 |

1A1 | 150 | 2 3 4 5 8 10 15 20 | 3-12 |

1A1 | 170 | 14 | 3-12 |

1A1 | 175 | 10 20 | 3-12 |

1A1 | 200 | 5 10 | 3-12 |

1A1 | 250 | 5 10 | 3-12 |

1A1 | 300 | 10 | 5-10 |

1A1 | 350 | 10 | 5 10 30 40 50 |

1A1 | 400 | 10 25 | 5 10 |

1A1 | 500 | 10 | 5 10 |

1A1 | 620 | 10 | 25 |

1A1 | 720 | 10 | 25 |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]