Case of CBN end mill cutter for machining H13 steel

what is H13 steel (X40 CrMoV5)?X40CrMoV5, also known as 1.2344 or AISI H13, is a widely used hot work tool steel known for its excellent toughness, thermal resistance, and wear resi…

2025-4-29 15:41:11

Case of CBN end mill cutter for machining H13 steel

what is H13 steel (X40 CrMoV5)?X40CrMoV5, also known as 1.2344 or AISI H13, is a widely used hot work tool steel known for its excellent toughness, thermal resistance, and wear resi…

2025-4-29 15:41:11

How to choose cutting tools for machining PCB board?

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the functionality of devices ranging from smartphones to aerospace systems. Machining these boards req…

2025-4-17 15:37:52

How to choose cutting tools for machining PCB board?

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling the functionality of devices ranging from smartphones to aerospace systems. Machining these boards req…

2025-4-17 15:37:52

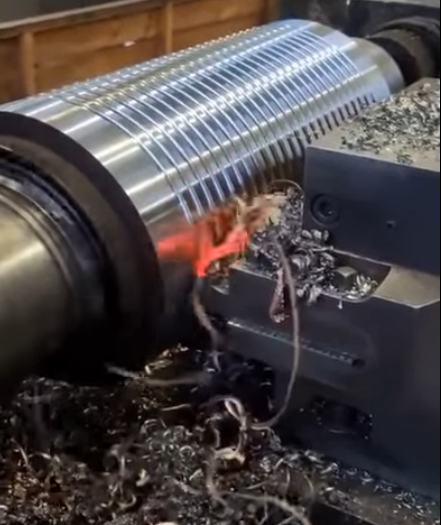

Why does the solid CBN inserts edge chipping when machining cast iron rolls?

Rolls use the pressure generated by a pair or a group of rollers when rolling to roll steel, so that the metal undergoes plastic deformation and obtains the finished product require…

2025-4-9 13:54:08

Why does the solid CBN inserts edge chipping when machining cast iron rolls?

Rolls use the pressure generated by a pair or a group of rollers when rolling to roll steel, so that the metal undergoes plastic deformation and obtains the finished product require…

2025-4-9 13:54:08

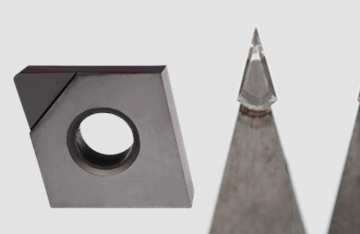

Chip breakers for CBN inserts - efficient processing assistants

Chip Breakers for CBN Inserts: Enhancing Efficiency in MachiningIn the realm of precision machining, the integration of chip breakers into Cubic Boron Nitride (CBN) inserts has revo…

2025-3-14 16:03:40

Chip breakers for CBN inserts - efficient processing assistants

Chip Breakers for CBN Inserts: Enhancing Efficiency in MachiningIn the realm of precision machining, the integration of chip breakers into Cubic Boron Nitride (CBN) inserts has revo…

2025-3-14 16:03:40

Application of diamond coating technology

Diamond coating technology has emerged as a transformative solution across various industries, offering unparalleled hardness, thermal conductivity, and chemical stability. By depos…

2025-2-28 10:29:14

Application of diamond coating technology

Diamond coating technology has emerged as a transformative solution across various industries, offering unparalleled hardness, thermal conductivity, and chemical stability. By depos…

2025-2-28 10:29:14

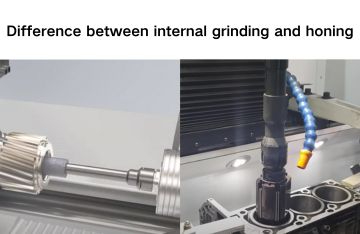

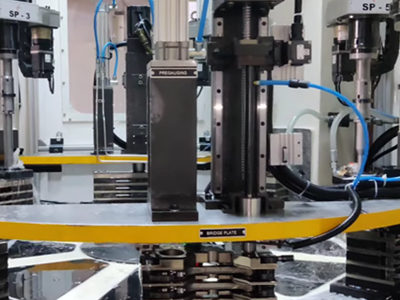

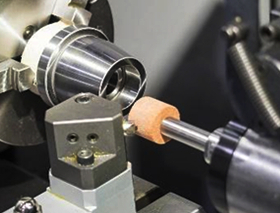

The Difference Between Honing and Internal Grinding

Application of internal grindingGrinding using abrasive particles coated or pressed on the grinding tool, the grinding tool and the workpiece move relative to each other under a ce…

2025-1-10 10:16:34

The Difference Between Honing and Internal Grinding

Application of internal grindingGrinding using abrasive particles coated or pressed on the grinding tool, the grinding tool and the workpiece move relative to each other under a ce…

2025-1-10 10:16:34

What are the applications of PDC cutter?

PDC cutter is also called diamond composite sheet (PDC-Polycrystalline Diamond Compact). Because PDC cutter has excellent anti-abrasion and impact resistance, it is widely used in g…

2024-11-26 14:51:17

What are the applications of PDC cutter?

PDC cutter is also called diamond composite sheet (PDC-Polycrystalline Diamond Compact). Because PDC cutter has excellent anti-abrasion and impact resistance, it is widely used in g…

2024-11-26 14:51:17

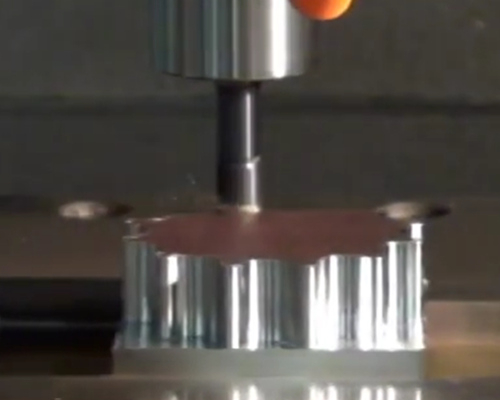

Why do wafers need to back grinding?

In the back-end process stage, wafers (silicon wafers with circuits on the front) need to be thinned on the back before subsequent dicing, bonding and packaging to reduce the packag…

2024-10-18 17:02:38

Why do wafers need to back grinding?

In the back-end process stage, wafers (silicon wafers with circuits on the front) need to be thinned on the back before subsequent dicing, bonding and packaging to reduce the packag…

2024-10-18 17:02:38

Honing process for honing connecting rods

What is connecting rod ?The connecting rod is an important component in the automobile engine, connecting the piston and the crankshaft, transmitting the reciprocating motion of the…

2024-9-29 16:22:25

Honing process for honing connecting rods

What is connecting rod ?The connecting rod is an important component in the automobile engine, connecting the piston and the crankshaft, transmitting the reciprocating motion of the…

2024-9-29 16:22:25

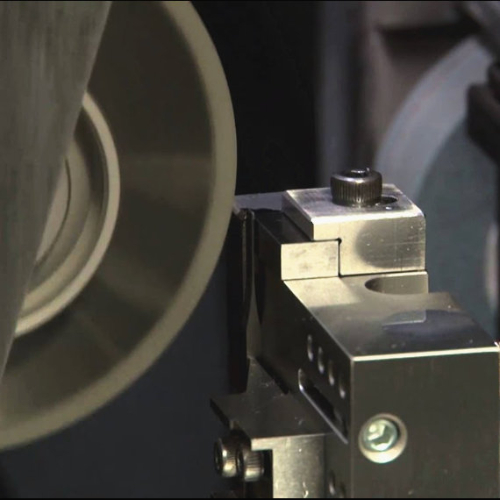

How to choose diamond grinding wheel for WC coating?

Tungsten carbide(WC) is one of the hardest carbon-based compounds. In its applications, we can find it used to make cutting tools, jewelry, abrasives, weapons, surgical instruments …

2024-8-16 10:44:31

How to choose diamond grinding wheel for WC coating?

Tungsten carbide(WC) is one of the hardest carbon-based compounds. In its applications, we can find it used to make cutting tools, jewelry, abrasives, weapons, surgical instruments …

2024-8-16 10:44:31

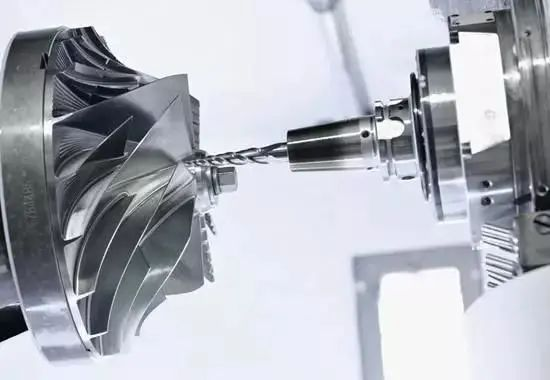

How to choose cutting tools for machining roll

With the development of the global economy and the advancement of industrialization, the demand for steel products continues to grow. Steel products such as steel plates, steel pipe…

2024-5-14 15:13:21

How to choose cutting tools for machining roll

With the development of the global economy and the advancement of industrialization, the demand for steel products continues to grow. Steel products such as steel plates, steel pipe…

2024-5-14 15:13:21

Processing of high-quality mirror surface roller

Taking the high-quality mirror-finished roller as an example, a wet belt polishing machine is used to focus on polishing the roller surface before electroplating to reduce shading a…

2024-3-6 16:30:02

Processing of high-quality mirror surface roller

Taking the high-quality mirror-finished roller as an example, a wet belt polishing machine is used to focus on polishing the roller surface before electroplating to reduce shading a…

2024-3-6 16:30:02

How to choose tools for titanium alloy cutting, grinding and polishing?

What is titanium alloy?The types of titanium alloys are roughly divided into three categories: alpha titanium alloys, beta titanium alloys, and alpha + beta titanium alloys.Currentl…

2024-1-25 13:58:16

How to choose tools for titanium alloy cutting, grinding and polishing?

What is titanium alloy?The types of titanium alloys are roughly divided into three categories: alpha titanium alloys, beta titanium alloys, and alpha + beta titanium alloys.Currentl…

2024-1-25 13:58:16

How to process ball head parts?

Optical profile grinding machines are widely used in modern manufacturing processes, also known as PG (Profile Grinder), which is a high-precision machining process. The processing…

2024-1-11 11:05:47

How to process ball head parts?

Optical profile grinding machines are widely used in modern manufacturing processes, also known as PG (Profile Grinder), which is a high-precision machining process. The processing…

2024-1-11 11:05:47

Why do cutting tools need to be coated?

In cutting processing, tool performance has a decisive impact on the efficiency, accuracy and surface quality of cutting processing. There seems to always be a contradiction between…

2023-12-22 10:31:00

Why do cutting tools need to be coated?

In cutting processing, tool performance has a decisive impact on the efficiency, accuracy and surface quality of cutting processing. There seems to always be a contradiction between…

2023-12-22 10:31:00

Grinding titanium alloy materials

Most aero-engine parts are made of titanium alloy materials. According to assembly requirements, finishing surface dimensional accuracy and surface roughness require grinding to ens…

2023-12-9 18:54:48

Grinding titanium alloy materials

Most aero-engine parts are made of titanium alloy materials. According to assembly requirements, finishing surface dimensional accuracy and surface roughness require grinding to ens…

2023-12-9 18:54:48

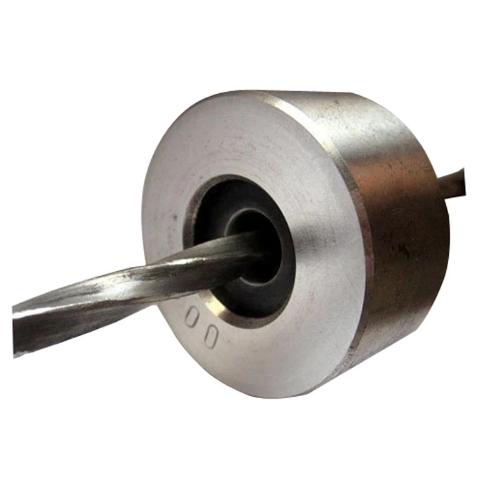

What is wire drawing die?

In metal pressure processing, the tool that forces the metal through the mold under the action of external force, compresses the metal cross-sectional area, and obtains the required…

2023-11-24 9:15:10

What is wire drawing die?

In metal pressure processing, the tool that forces the metal through the mold under the action of external force, compresses the metal cross-sectional area, and obtains the required…

2023-11-24 9:15:10

What is glass-ceramic?

Glass-ceramics is a glass with a specific composition that undergoes microcrystallization heat treatment to induce the precipitation of microcrystalline phases at a certain temperat…

2023-11-16 15:27:11

What is glass-ceramic?

Glass-ceramics is a glass with a specific composition that undergoes microcrystallization heat treatment to induce the precipitation of microcrystalline phases at a certain temperat…

2023-11-16 15:27:11

Internal cylindrical grinding questions-roundness and taper

The most common problem with internal grinding is the taper produced by grinding.When the ground hole is not straight enough, there will be a taper problem. The inner diameter gradu…

2023-11-7 14:36:14

Internal cylindrical grinding questions-roundness and taper

The most common problem with internal grinding is the taper produced by grinding.When the ground hole is not straight enough, there will be a taper problem. The inner diameter gradu…

2023-11-7 14:36:14

Grinding wheel marking method

There is a unified international standard for the marking of grinding wheels. Its main elements include: shape, size, abrasive, particle size, hardness, structure, bonding agent, an…

2023-11-1 16:22:21

Grinding wheel marking method

There is a unified international standard for the marking of grinding wheels. Its main elements include: shape, size, abrasive, particle size, hardness, structure, bonding agent, an…

2023-11-1 16:22:21

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]