Application field:

3c field, aerospace, automotive industry, etc.

Machining Materials:

Non-ferrous metal materials, non-metal materials, composite materials, etc.

Advantage:

High removal rates, Improved finished, Improved productivity, Reduced tooling cost.

Polycrystalline diamond is sintered and pressed by diamonds of different particle sizes and binders. Because of its low affinity with non-ferrous metals and non-metallic materials, it is mainly used for cutting non-ferrous metals and non-metallic materials.

PCD inserts are the best choice for cutting other non-ferrous metals, such as aluminum alloys, non-metallic fiber materials, etc., which can obtain faster cutting speed and longer tool life, as well as high surface quality and processing accuracy of the processed materials.

MoreSuperHard through huge R&D investment and close cooperation with customers, we can find the latest method to transform the cutting-edge characteristics of superhard materials into products with innovative performance, which have obvious performance and price advantages compared with competitors' products. Imported element 6, GE raw materials. Use high-precision peripheral grinder to produce high-quality PCD tools.

Specifications of PCD cutting tools

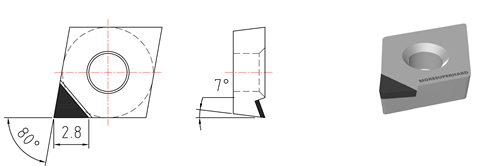

Type | Size | ||||

D | S | R | D1 | SL | |

CCGW060202 | 6.35 | 2.38 | 0.2 | 2.8 | 3.0 |

CCGW060204 | 6.35 | 2.38 | 0.2 | 2.8 | 3.0 |

CCGW09T304 | 9.525 | 3.97 | 0.4 | 4.4 | 3.0 |

CCGW09T308 | 9.525 | 3.97 | 0.8 | 4.4 | 3.0 |

CCGW120404 | 12.7 | 4.76 | 0.4 | 5.5 | 3.0 |

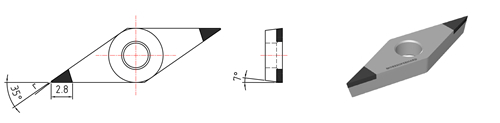

Type | Size | ||||

D | S | R | D1 | SL | |

VCGW110302 | 6.35 | 3.97 | 0.2 | 2.8 | 3.0 |

VCGW110304 | 6.35 | 3.97 | 0.4 | 2.8 | 3.0 |

VCGW160404 | 9.525 | 4.76 | 0.4 | 4.4 | 3.0 |

VCGW160408 | 9.525 | 4.76 | 0.8 | 4.4 | 3.0 |

VCGW160412 | 9.525 | 4.76 | 1.2 | 4.4 | 3.0 |

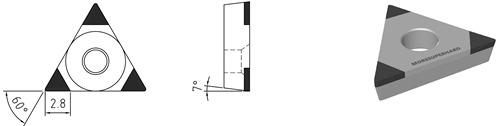

Type | Size | ||||

D | S | R | D1 | SL | |

TCGW090202 | 5.56 | 2.38 | 0.2 | 2.5 | 3.0 |

TCGW090204 | 5.56 | 2.38 | 0.4 | 2.5 | 3.0 |

TCGW110202 | 6.35 | 2.38 | 0.2 | 2.8 | 3.0 |

TCGW110204 | 6.35 | 2.38 | 0.4 | 2.8 | 3.0 |

TCGW110208 | 6.35 | 2..38 | 0.8 | 2.8 | 3.0 |

TCGW110302 | 6.35 | 3.18 | 0.2 | 2.8 | 3.0 |

TCGW110304 | 6.35 | 3.18 | 0.4 | 2.8 | 3.0 |

TCGW116T304 | 9.525 | 3.97 | 0.4 | 4.4 | 3.0 |

TCGW16T308 | 9.525 | 3.97 | 0.8 | 4.4 | 3.0 |

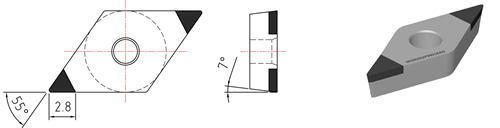

Type | Size | ||||

D | S | R | D1 | SL | |

DCGW070202 | 6.35 | 2.38 | 0.2 | 2.8 | 3.0 |

DCGW070204 | 6.35 | 2.38 | 0.4 | 2.8 | 3.0 |

DCGW070208 | 6.35 | 2.38 | 0.8 | 2.8 | 3.0 |

DCGW110302 | 9.525 | 3.97 | 0.2 | 4.4 | 3.0 |

DCGW110304 | 9.525 | 3.97 | 0.4 | 4.4 | 3.0 |

DCGW110308 | 9.525 | 3.97 | 0.8 | 4.4 | 3.0 |

DCGW11T302 | 9.525 | 3.97 | 0.2 | 4.4 | 3.0 |

DCGW11T304 | 9.525 | 3.97 | 0.4 | 4.4 | 3.0 |

DCGW11T308 | 9.525 | 3.97 | 0.8 | 4.4 | 3.0 |

Cutting Parameters

Material | Vc (m/min) | f (mm/U) | |

Aluminum Alloys: Si <12% | Turning (roughing) | 800-3000 | 0,1-0,6 |

Turning (finishing) | 800-3000 | 0,03-0,2 | |

Aluminum Alloys: Si >12% | Turning (roughing) | 300-9000 | 0,1-0,4 |

Turning (finishing) | 300-9000 | 0,03-0,2 | |

Copper, Bronze, Brass, Zinc and Magnesium Alloys | Turning (roughing) | 600-1200 | 0,1-0,4 |

Turning (finishing) | 700-1500 | 0,05-0,4 | |

Solid Carbide | Turning (roughing) | 20-25 | 0,1-0,3 |

Turning (finishing) | 20-30 | 0,05-0,2 | |

Processing case

Processing parts | Processing parts | Workpiece material | Model | Cutting parameters |

automobile engine piston | outer circle and end face | Si-Al alloy (Si 17%) | CCGW09T308 | VC =750m/min Fr= 0.2 mm/r |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]