Diameter Range : Φ4 – Φ30 mm (customized available)

Tolerance: Up to ±0.002 mm

Helix Angle: Customized

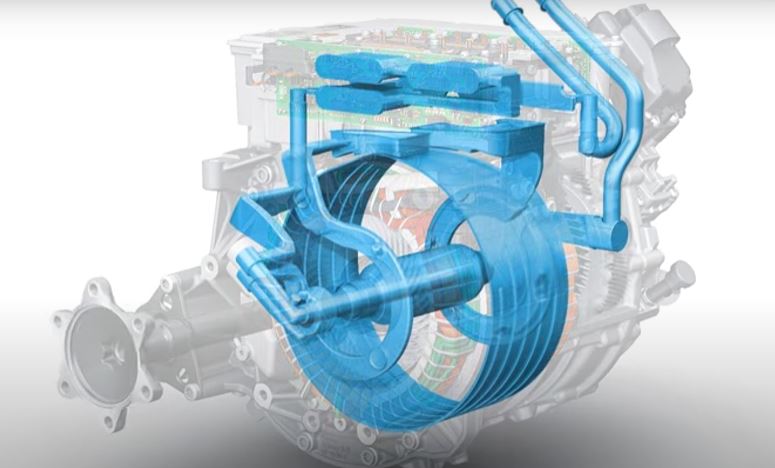

The working principle of the NEV water pump is based on centrifugal force. When the motor drives the pump impeller to rotate, the blades inside the impeller push water toward the edge of the impeller. Under the action of centrifugal force, the water is thrown out of the impeller and enters the pump's outlet pipe. At the same time, a low-pressure area is formed at the center of the impeller, allowing water to be sucked into the impeller from the inlet pipe. In this way, water is continuously sucked in and thrown out, realizing water circulation. In NEVs, the water pump is usually driven by a motor, and the rotational speed of the motor determines the flow rate and pressure of the water pump. Generally, the rotational speed of NEV water pumps is relatively high to meet the requirements of the cooling system.

PCD reamer ensures tight sealing, low friction, and longer component lifespan, which are critical for the efficiency and durability of NEV water pump systems.

-

Application of PCD reamer:

Machining material: Aluminum alloy, silicon aluminum alloy, copper alloy, composite materials.

Application field:

-New energy vehicle water pump housing

-Cooling system components

-Precision automotive aluminum parts

-Pump seat holes, shaft holes, and sealing holes

0Precision automotive parts requiring ultra-smooth holes and high positional accuracy

-Ideal for high-speed reaming and fine finishing of bore holes with strict dimensional accuracy.

Difficulties in Part Machining

1. Due to the small bore diameter of the workpiece (∅20.04), the indexable fine boring unit is not applicable. Therefore, an integral tool must be used for machining.

2. The bore diameter has a strict tolerance of only 0.03. Meanwhile, the roundness error of the bore is required to not exceed 0.05, and a specific R-angle structure needs to be machined at the bottom of the bore.

3. The workpiece bore with a diameter of ∅20.04mm not only has strict tolerance requirements but also needs to ensure the surface roughness is between Rz8 and Rz10. Conventional tools are difficult to meet the above process requirements simultaneously.

Design Features

1. To meet the part's hole wall roughness requirements (Rz8–Rz10), the reamer is designed with precision micro-adjustment structured breaking teeth. This structure can effectively control the cutting state and ensure the surface machining quality.

2. Aiming at the part's characteristics of small bore diameter tolerance and high roundness requirements, the reamer adopts a breaking tooth structure design. This design effectively distributes cutting force, reduces machining errors, and ensures the stability of bore diameter size and shape accuracy.

3. Compared with the single-flute boring tool solution used by the customer during sampling, this reamer significantly improves cutting efficiency through multi-tooth collaboration and breaking tooth design, while ensuring machining quality.

Dimensions of PCD reamer

Diameter (mm) | Shank Type | Cutting Edge | Application |

Φ4 – Φ6 | Straight shank | PCD | Small holes, valve seat bores |

Φ6 – Φ12 | Straight / Taper shank | PCD | Water pump housing holes |

Φ12 – Φ20 | Modular or Welded type | PCD | Cooling system precision bores |

Φ20 – Φ30 | Custom design | PCD | Large hole finishing, sealing surface reaming |

PCD straight shank reamer | |||||

D (Shank ) | d (cutting edge) | L (Total length) | L1 (Cutting depth) | L2 ( edge length) | Z (number of cutting edge) |

6 | 4 | 80 | 40 | 6 | 2 |

6 | 5 | 80 | 40 | 6 | 2 |

6 | 6 | 80 | 40 | 6 | 2 |

8 | 7 | 80 | 40 | 6 | 2 |

8 | 8 | 80 | 40 | 6 | 2 |

10 | 9 | 80 | 40 | 6 | 2 |

10 | 10 | 80 | 40 | 6 | 2-4 |

12 | 12 | 80 | 40 | 6 | 2-4 |

14 | 14 | 80 | 40 | 6 | 2-4 |

16 | 15 | 80 | 40 | 6 | 2-4 |

20 | 20 | 80 | 40 | 6 | 2-4 |

26 | 25 | 80 | 40 | 6 | 2-4 |

32 | 30 | 80 | 40 | 6 | 2-4 |

Case of PCD reamer for NEV water pump

Part Information and Customer Requirements | |

Processed Part | Water Pump |

Processed Material | AlSi9Cu3 |

Machine Tool Equipment | Vertical Machining Center (VMC) |

Cooling Method | Internal Cooling |

Machining Position | Bearing Bore |

Cutting Parameters | |

Tool Diameter | D20.04 |

Spindle Speed | S2000 |

Feed Rate | F900 |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]