Tungsten carbide is a kind of material with high strength and excellent abrasion resistance. It is basic composition is wc-co (tungsten carbide), the important factor of super hard alloy structure depends on C (carbon) content.

According to the characteristics of hard alloy, precision cold stamping mold is often used as the core key parts of the mold, surface grinding is the mold part processing all procedure in the foundation. More super hard company has many years of experience in grinding wheel for mold processing. Share follow method of grinding wheel for surface mold as below.

Size of rough processing hexahedron:

There is an extra 0.05mm allowance for finishing on the basic size of the drawing.

The work piece parallel and perpendicular: ∥、⊥≤0.005mm

The dimension tolerance of the finished hexahedron is: +0.001/0~+/-0.002mm

parallel and perpendicular: //、⊥≤0.002mm

Surface roughness Ra≤0.15 microns

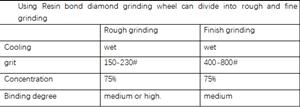

The sharper the grinding wheel is, the higher the machining efficiency will be. If need the sharpness and grinding efficiency should choose grinding wheel with lower "union degree". If need longer service life can choose grinding wheel with higher "binding degree"

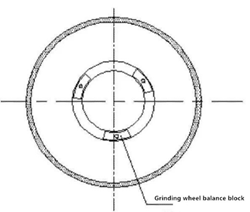

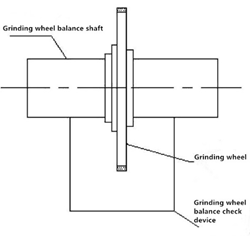

In order to eliminate the beating, ensure the stable rotation of the grinding wheel uniform loss, make the work piece surface roughness uniform, avoid left a jump mark on the surface after processing.

Picture 1. Grinding wheel with flange installed

Picture 2. Grinding wheel static balance

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]