The superhard abrasive wheel has excellent grinding performance and strong anti-wear ability, so it does not need constant dressing, but it is more difficult to dressing after initial installation and blunt use. In recent years, the extensive application of superhard materials in production engineering and science and technology has led to a sharp increase in the application of superhard abrasive wheels, and the dressing of grinding wheels has become increasingly acute, which has become an important research topic in the world. Up to now, on the basis of before conventional dressing method, developed a lot of new dressing method again.

The dressing of superhard abrasive wheel is usually divided into two procedures: shaping and sharpening. Shaping is to carry out micro-cutting on the grinding wheel so that the grinding wheel can reach the required geometric precision and the abrasive tip can be slightly broken to form a sharp grinding edge. Sharpening is to remove the binding agent between the grinding grains, so that there is a certain chip space between the grinding grains, and make the grinding edge protrude out of the binding agent to form the cutting edge. For bonded loose superhard abrasive wheels (such as ceramic bonded diamond or CBN grinding wheels), shaping and sharpening can be performed simultaneously in one process. For bonded densified superhard abrasive wheels (such as resin or metal-bonded diamond wheels), shaping and sharpening must be performed separately.

Ceramic bond CBN (bond loose type) grinding wheel can be dressed with single grain diamond or roller, which is easy to realize.

Used for dressing super hard abrasive grinding wheel with resin bond. The grinding wheel should rotate at low speed when dressing. Otherwise, the dressing effect is not good and the diamond pen wears away quickly. The surface of the grinding wheel dressed by this method is relatively smooth, with poor grinding performance and low precision of shape and size, so this method can only be used in the absence of other dressing conditions.

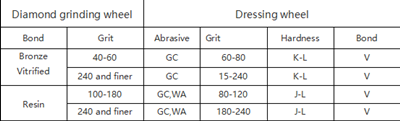

The grinding wheel used for shaping is a green silicon carbide or white alumina ceramic bonded grinding wheel. The grit of the grinding wheel should be selected according to the grit of the super-hard grinding wheel. If the grinding wheel of super hard abrasive is fine in grit, a finer dressing wheel should be selected. The dressing mechanism of the rolling shaping method is different from that of the diamond pen shaping method. The former mainly rely on pressure to break and fall off the abrasive particles, while the latter mainly rely on shear force. Due to the need for larger rolling pressure when dressing by rolling shaping method, the requirement of the rigid parts of the grinding machine is better, otherwise, the contour shape accuracy of the dressed grinding wheel is lower.

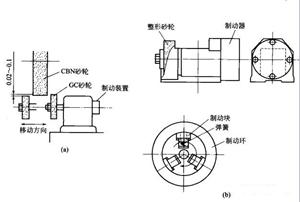

In order to improve the dressing effect of rolling shaping method, a braking dressing device can be used, as shown in figure (a). When the dressing grinding wheel presses the CBN grinding wheel with a certain pressure, the shaping grinding wheel will rotate with the CBN grinding wheel. In addition, the grinding wheel also does reciprocating movement, with a certain amount of rolling pressure dressing. The purpose of installing the brake on the shaper wheel shaft is to generate the relative speed between the shaper wheel and the CBN wheel. FIG. (b) shows the diagram of the brake. The brake block is applied to the brake ring by the spring force, and the speed of the shaping grinding wheel is reduced by the friction action. The higher the relative speed of the grinding wheel and the CBN grinding wheel, the higher the shaping efficiency.

This kind of method also can be used at the same time repair sharp, it is a kind of commonly used dressing method. The grinding wheel can be dressed with silicon carbide or corundum whetstone, or dressed with diamond, silicon carbide or corundum grinding wheel driven by power.

When the ordinary grinding wheel is used as the dressing wheel, the shaping accuracy is slightly lower, and the dressed wheel has good grinding performance. It is suitable for dressing the grinding wheel with low surface accuracy or grinding ability. When diamond grinding wheel is used as dressing wheel, the shaping accuracy is good, but the grinding ability of the grinding wheel being repaired is poor. Therefore, it is only used for dressing the grinding wheel with higher requirements of profile accuracy. In order to improve the grinding ability, both can be used, that is to say, after the diamond grinding wheel is reshaped, the ordinary grinding wheel is used to repair.

When dressing resin bonded CBN grinding wheel with diamond grinding wheel as a dressing tool, dressing efficiency is very high, but the surface of the dressed sand is smooth, the number of abrasive particles per unit area is small, and the grinding ability is poor. Otherwise, it is easy to annealing the workpiece during initial grinding. When dressing CBN grinding wheel with corundum or silicon carbide grinding wheel, although the dressing efficiency is low, the grinding performance of the dressed grinding wheel is good.

The hardness and particle size of dressing wheel have great influence on dressing efficiency, dressing effect and grinding performance. The hardness of dressing wheel is improved and the dressing efficiency is improved, but the grinding performance of the grinding wheel is correspondingly reduced. The grinding wheel surface is relatively smooth and the grinding ratio is reduced. The particle size of dressing wheel has little influence on dressing efficiency and grinding performance of grinding wheel. When the dressing wheel particle size is close to that of the grinding wheel being repaired, the grinding performance is better. Dressing conditions and grinding conditions are the same as above.

Using mild steel grinding and shaping, it can also be sharpened. It is not suitable to use this method to trim the grinding wheel with higher precision of profile due to the large number of abrasive particles falling off during shaping. Double roller method is to use two mild steel roller, when dressing the two roller steering the same, but the speed is different. If the linear speed of the dressed grinding wheel is Vsd, then the linear speed of one mild steel roller is Vsd+V and the other is vsd-v. Therefore, there are two equal and opposite dressing forces on the tangent direction of the grinding wheel being dressed. In this way, the dressed grinding wheel will not generate additional dry disturbance torque, which can ensure the smooth shaping process and improve the shaping quality.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]