Conventional cylindrical grinding uses the center holes at both ends of the workpiece to support the workpiece between the head of the grinder and the center of the tailstock. During grinding, the workpiece rotates driven by the spindle while the grinding wheel feeds horizontally.

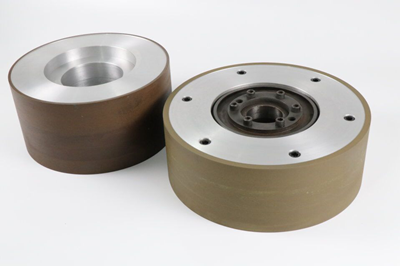

The centerless external circular mill does not have a head frame and a tail frame, but supports the workpiece by a support plate and a guide wheel, and grinds with a grinding wheel. Centerless grinding method is composed of grinding wheel, adjusting wheel and workpiece support, the adjusting wheel controls the rotation of the workpiece and causes the workpiece to feed at a speed. The workpiece support supports the workpiece in grinding. High productivity of centerless cylindrical grinder. Mostly used in mass production, easy to achieve automation.

1. Continuous processing, no need to return the knife, such as short time clamping workpiece, high productivity.

2. Bracket and guide wheel positioning mechanism is more rigid than the ordinary cylindrical grinder center and center frame mechanism, and the cutting quantity can be larger, it is also beneficial to the machining of long and thin shaft workpiece and easy to realize high speed grinding and strong grinding.

3. The workpiece of centerless cylindrical grinder is located on the positioning mechanism by the outer circle. The grinding amount is the allowance on the diameter of the workpiece, therefore, the impact of grinding wheel wear, compensation of feeding mechanism and repeated positioning accuracy error of cutting mechanism on the diameter and size accuracy of parts, there is no need to punch the center hole, and it is easy to automate the loading and unloading in advance.

4. Grinding wheel centerless grinder through the mechanism, can be used to increase the machining allowance, In the process of cutting into the grinding, the complex surface can be successively shaped grinding or multi-wheel grinding, high productivity, wide range of applications.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]