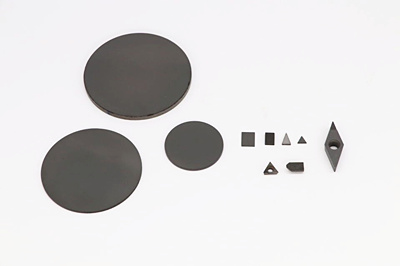

Diamond tool material

Diamond is an isomer of carbon and is one of the hardest materials ever found in nature. With high hardness, high wear resistance and high thermal conductivity, diamond tools are widely used in the processing of non-ferrous and non-metallic materials. Especially in the high speed cutting of aluminum and ALSI alloy, diamond tools are the main cutting tools that are hard to replace. Diamond tools that can achieve high efficiency, high stability and long life are indispensable tools in modern CNC machining.

Types of diamond tools

(1)Natural diamond cutting tools: natural diamond as a cutting tool for hundreds of years of history, natural single crystal diamond tool after fine grinding, can grinding extremely sharp blade, blade radius of 0.002 mu m, can realize the ultra-thin cutting, can work out high precision and low surface roughness of workpiece, is accepted, the ideal and Irreplaceable ultra-precision machining tools.

(2)The PCD diamond tool: natural diamond is expensive, polycrystalline diamond(PCD) is widely used in machining, since the early 1970 s, the use of high temperature and high pressure synthesis technology of the preparation of polycrystalline diamond (PCD) blade after successful development, on many occasions, natural diamond cutting tool has been replaced by artificial polycrystalline diamond. PCD is a rich source of raw materials that cost between a tenth and a tenth of the price of natural diamonds. PCD tool cannot grind extremely sharp edge, the surface quality of processed workpiece is not as good as natural diamond, now the industry cannot easily manufacture with chip groove PCD blade. Therefore, PCD can only be used for fine cutting of non-ferrous and non-metallic metals, and it is difficult to achieve ultra-precise mirror cutting.

(3)CVD diamond tools: CVD diamond technology has been available in Japan since the late 1970s to early 1980s.CVD diamond refers to the synthesis of diamond film by chemical vapor deposition (CVD) on heterogeneous matrix (such as cemented carbide, ceramics, etc.). CVD diamond has exactly the same structure and characteristics as natural diamond. Compared with natural diamond, the properties of CVD diamond are very close to that of natural single crystal diamond and polycrystalline diamond (PCD).“

Properties of diamond tools

(1)High hardness and wear resistance: natural diamonds are the hardest materials found in nature. Diamond has a very high wear resistance, processing of high hardness materials, the life of diamond tools for carbide tools 10~ 100 times, even up to several hundred times.

(2)With very low friction coefficient: the friction coefficient between the diamond and some non-ferrous metals is lower than other cutting tools, low friction coefficient, processing deformation is small, can reduce the cutting force.

(3)Very sharp cutting edge: the cutting edge of diamond tools can be sharpened very sharp, natural single crystal diamond tools up to 0.002 ~ 0.008 cm, for ultra-thin cutting and ultra-precision machining.

(4)High thermal conductivity: high thermal conductivity and thermal diffusivity of diamond, easy to dissipate cutting heat, cutting part of the tool temperature is low.

(5)With low thermal expansion coefficient: the thermal expansion coefficient of diamond is several times smaller than that of cemented carbide, and the change of tool size caused by cutting heat is very small, which is particularly important for precision and ultra-precision machining with high dimensional accuracy requirements.

Application of diamond tools

Diamond tools are often used for fine cutting and boring of non-ferrous and non-metallic materials at high speed. Suitable for processing various wear-resistant nonmetals, such as glass fiber reinforced plastic powder metallurgy blank, ceramic materials, etc. Various wear resistant non-ferrous metals, such as various silicon aluminum-alloy; All kinds of non-ferrous metal finishing processing.

The deficiency of diamond tools is poor thermal stability, cutting temperature more than 700℃ ~ 800℃, will completely lose its hardness; In addition, it is not suitable for cutting ferrous metals, because diamond (carbon) is easy to interact with iron atoms at high temperature, so that carbon atoms are converted into graphite structure, the tool is easily damaged.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]