1.Gear milling

The use of a disc-shaped modular milling cutter or a finger milling cutter to mill teeth belongs to the forming method. The cross-sectional shape of the milling cutter teeth corresponds to the shape of the gear teeth. This method has low processing efficiency and processing accuracy, and is only suitable for single-piece small batch production.

2.Formed grinding teeth

It also belongs to the forming method, because the grinding wheel is not easy to dress, so it is used less.

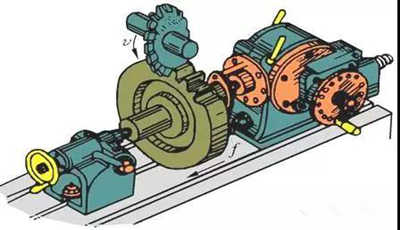

3.Hobbing

It belongs to the spreading method, and its working principle is equivalent to a pair of helical gears meshing. The prototype of the gear hob is a helical gear with a large helical angle. Because the number of teeth is very small (usually the number of teeth z = 1), the teeth are very long, and a worm with a small helical angle is formed around the shaft, which is then slotted and The shovel teeth become a hob with cutting edge and clearance angle

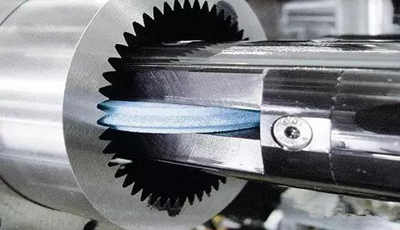

4.Shaving

Shaving is a commonly used finishing method for non-hardened tooth surfaces in mass production. Its working principle is to use the shaving cutter and the gear to be processed for free meshing movement, and by virtue of the relative slip between the two, shave very fine chips from the tooth surface to improve the accuracy of the tooth surface. Shaving teeth can also form drum-shaped teeth to improve the position of the tooth surface contact area.

5. Gear shape

Gear shaping is a kind of gear cutting technology that uses the forming method in addition to hobbing. During gear shaping, the gear shaping knife and the workpiece are equivalent to the meshing of a pair of cylindrical gears. The reciprocating motion of the gear shaper is the main motion of the gear shaper, and the circular motion made by the gear shaper and the workpiece according to a certain proportional relationship is the feed motion of the gear shaper.

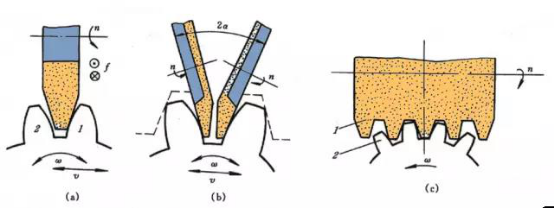

6. Tooth grinding

Spreading method grinding gear cutting motion is similar to hobbing, is a tooth shape finishing method, especially for hardened gears, often the only finishing method. Spreading method grinding teeth can be ground with worm grinding wheel, cone grinding wheel or dish grinding wheel.

The picture above is (a.) Conical grinding wheel grinding teeth, (b.) Butterfly grinding wheel grinding teeth, (c.) Worm grinding wheel grinding teeth.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]