摘自: https://mp.weixin.qq.com/s/EF28-ru8MhTWr4zi8DqjBQ

● originally used cemented carbide forming tools for cutting. The main reasons for tool scrapping are sticky chips, tool tip wear, poor surface roughness, and tool marks. The machining dimensional accuracy is poor and unstable. Products need to be fully inspected before they can be delivered. The bearing hole needs to be bored to meet the accuracy requirements. low efficiency.

● After using More Super Hard PCD forming tools, PCD tools have excellent wear resistance, high surface finish and dimensional stability, tool life is improved, and cutting efficiency is doubled. PCD tool has high dimensional stability and dimensional accuracy is as high as 0.003. Save a lot of processing man-hours.

More Super Hard PCD forming tools VS cemented carbide forming tools | |

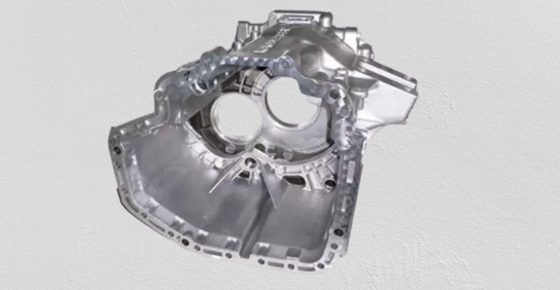

Workpiece: aero engine gearbox, cast aluminum A380 | Workpiece: aero engine gearbox, cast aluminum A380 |

Tools used: More Super Hard PCD forming tools | Tools used: cemented carbide forming tools |

Number of tools required: 11 | Number of tools required: 14 |

Processing time: 2’23” | Processing time: 3’47” |

Cost per tool: 0.8 | Cost per tool:1.3 |

Roughness: Ra0.4μm | Roughness: Ra1.6μm |

Cutting fluid: water-soluble cutting fluid | Cutting fluid: water-soluble cutting fluid |

Tool life: 35,000 pieces | Tool life: 8000 pieces |

More Super Hard PCD forming tools are 4 times of hard forming tools More Super Hard CBN inserts are 1.5 times more efficient than carbide inserts More Super Hard CBN inserts have two higher surface roughness levels, with a dimensional accuracy of up to 0.005mm | |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]