Honing is usually used in machining operations where round holes are accurately sized and have a specified surface gloss. Here answer the five frequently asked questions about the honing process.

Hole Processing

As one of the most common machining operations, the manufacturer offers a variety of machining options. According to the aperture and surface finish tolerances, you can choose drilling, milling, EDM or CNC machining to achieve high quality results.

For example, a hole drilled with a 0.5 inch bit may have a range of ±0.002 inches or greater than 0.006 inches. But continuous reaming produces a smoother surface finish with an aperture of ±0.0002 inches. A similar result can be achieved by reaming or boring the hole, while EDM is more accurate, producing an aperture of ±0.0005 inches.

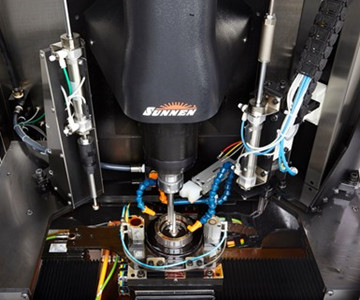

According to Sunnen, honing is typically required to achieve bore diameter tolerances of ±0.0002 inch or tighter with high quality surface finishes. (All photos: Sunnen)

However, for high surface roughness and accuracy requirements, you can choose honing. According to information provided to this article by honing equipment manufacturer Sunnen, EDM holes usually require further processing to make their surfaces smoother. The process is also relatively slow. The results obtained through boring or reaming are of high quality, but not always consistent.

Honing can achieve all the above requirements: stable to achieve a tolerance of ±0.0002 inches or less of the aperture, and at the same time have a high quality surface finish.

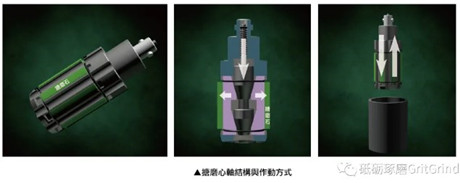

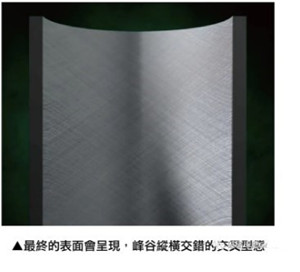

Honing is a finishing process in which a rotating tool (mandrel) fitted with abrasive is used to move in and out of the holes. In this process, the abrasive expands, bit by bit, removing the workpiece, allowing the hole to reach the appropriate size and surface thickness. The final surface will have a crisscross pattern of peaks and valleys. Oil can adhere to the surface of the valley, in connection to maintain lubrication, such as in the engine cylinder piston action.

Although honing has been invented for many years and gradually developed, users still have some questions to answer. Here are five of the most common wear - out questions:

1. Honing is used in which area?

Like engine cylinders and cylinder liners, in order to actually seal the piston rings, they would need honing. Parts of the fuel system of diesel engines are often honed as well, as honing allows tighter control of the clearance between holes and fittings.

The resulting high-pressure fuel system means that more fuel is atomized and used to its full potential, improving fuel efficiency and engine performance, and reducing carbon emissions.

Honing tools should be choosed according to its workpiece

Honing is also often used in hydraulic plug valves (such as heavy equipment, agricultural machinery and aerospace flight and landing gear control systems) because the gap between the hydraulic valve body and the slide valve needs to be tight to reduce the required sealing area. Honing also creates an appropriate surface finish for the oil seal and prevents oil leakage by reducing the clearance.

Honing also improves the diameter of the rifling hole and the finish of the barrel before rifling operation. In this way, the rifle can be guaranteed to shoot consistently, so as to obtain better shooting effect. The process is also useful for gears, small engines, brake drums, compressors, oil and gas flow lines, and many other applications.

2. What adverse drilling conditions can use honing solve?

Honing can solve a lot of drilling problems. Includes aperture, bell mouth, ripple, taper, rainbow changing color, barrel shape, reamer vibration, boring and non circular hole. The shape is honed to make the fittings work quieter and more efficiently when connected.

Honing can also correct the errors caused by the front part of the machining because it does not require a jig or calibration and there is no limit to the length of the hole.

Other machining processes (such as grinding and boring) may crack the surface of the metal to a depth of 0.002 inches. In addition, tool wear can also lead to hole surface hardening during machining. While honing is a milder way of machining, in which little heat is generated to avoid deforming the holes.

3. What degree of surface finish can be achieved by honing

Honing can provide precise control over the finish, texture and appearance of the surface. The Angle of the cross lining can be adjusted by changing the main shaft speed and the forward speed of the honing tool.

Some will require a large Angle of the cross grain in the hole, while others will require a small Angle. The depth and roughness of the cross lines depend on the abrasive particle size of the honed stone. The larger the particle size, the rougher the surface. Using very fine abrasive, mirror polishing with almost no visible surface texture can be achieved.

Honing is suitable for large-scale production of automatic machines

As mentioned earlier, cross-lining produced by honing is beneficial for applications such as engine cylinder bore. Cross-lining preserves some of the oil on the surface and helps lubricate and seal the piston rings appropriately. If the oil does not adhere well to the smooth cylinder bore surface, premature wear or failure of components may result.

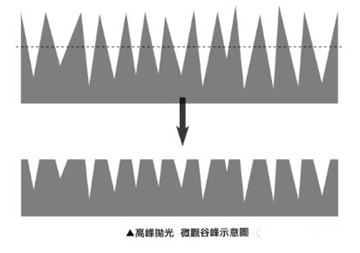

If necessary, special tools can be used for the second honing and peak polishing according to the first line, so that the peak of the line is more even, while the depth of the valley remains unchanged. Most engine cylinders undergo peak polishing, which increases the bore surface support area.

This means that the "run-in" process of the piston is no longer required, and the tiny peaks that were previously worn off do not enter the oil at startup.

4. How to establish an effective and consistent honing process?

Just like CNC machining, all kinds of problems must be solved before developing or optimizing honing operations:

the materials, dimensions and shapes of the workpieces?

Output?

The removal amount of materials?

The hole tolerance of the finished products?

The degree you required of surface finish?

The answers to these questions will affect the choice of suitable machines, fixtures, tools, grindstones, honing oil or coolant; And machining parameters in the honing process, such as spindle speed or feed speed. The choice of honing stone should be made according to the material of the workpiece, the required tolerance and the expected amount of removal. Grindstone specifications and milling cutter, turning tool specifications, according to abrasive, particle size and binder and there are a variety of specifications can be selected.

5. Effect of lubricating agent on honing?

Honing oil and water-based coolant provide the lubrication needed in the machining process. It also removes cuttings and brings new abrasive to the surface of the stone for optimum cutting performance.

The high quality honing oil, rich in surfactants, provides the necessary lubrication to improve the application of the honing force so that a harder abrasive or faster cutting speed can be used for grinding. The lubricant and sulfur extreme pressure additives used together, can prevent the workpiece melting adhesion and tear. It also cleans the grindstone at the same time, resulting in a consistent surface finish. Specially honed honing oil can also be used in some harsh processing conditions, such as those that are prone to scratches.

Honing oil comes in a variety of formulations and has a variety of viscosity. Environmentally friendly oils, on the other hand, are 100% plant based.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]