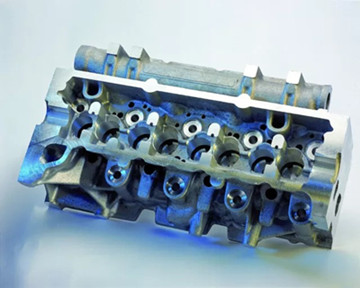

The design of the cylinder head is the key to reducing fuel emissions and meeting stringent government regulations. The valve seat hole of the valve guide on the cylinder head part is a key hole, which has a great impact on ensuring the working performance of the engine and reducing fuel consumption. Therefore, there are strict requirements for the material, dimensional accuracy, shape accuracy and coaxiality of the valve seat hole and the sealing cone.

The challenge you face

1. High-quality and reliable processing of valve seat bottom holes and pipe bottom holes

2. Meet quality and productivity requirements when finishing valve seats and duct holes

Solutions we bring you

1. High-quality and reliable processing of valve seat bottom holes and pipe bottom holes

Non-standard PCD reamer

For the precision machining of the bottom hole of the valve seat conduit that requires strict dimensional tolerances and precise geometric tolerances, this customized tool can achieve the required quality with the shortest machining cycle. The tool is dynamically balanced and equipped with an internal cooling channel. The PCD tip can be reground after wear to restore the original working condition, thereby achieving the longest available tool life.

Advantages: Achieve high-quality output at a lower cost.

2. Meet quality and productivity requirements when finishing valve seats and duct holes

Non-standard reamer

The non-standard reamer integrates HSK tool holders and combines multiple processing. The catheter hole reamer can be single-edged or multi-edged, made of cemented carbide or PCD. When processing sintered steel valve seats, a patented adjustable tool holder is used to achieve maximum safety. 4 The CBN blade with the entire edge is combined to finish machining the different chamfers on the valve seat, and the tool is subjected to precision dynamic balancing treatment to minimize the wear of the spindle.

Advantages: Improve the stability of processing while reducing the cost of each piece.

Featured Case

Machining of valve seat hole of engine cylinder head valve guide

Guide reamer: diameter D4.97/D29.4

Blade: non-standard PCD reamer and CBN blade

Cutting parameters:

Vc= 105 (guide)/ 124 (seat) m/min;

ap = 0.10--0.15 mm;

N = 5570/1360 rpm

Fr= 0.12 (guide)/ 0.07 (seat guide) - 0.05 (seat precision) mm/r;

F= 668/95/68 mm/min

Tool life:

Valve seat CBN blade: 800-1000 pcs

Catheter PCD reamer: 800-1000 pcs

Fine reamer: diameter D5/D29.5

Blade: non-standard PCD reamer and CBN blade

Cutting parameters:

Vc= 95 (guide) / 120 (seat) m/min;

Fr= 0.12 (guide) / 0.11 (seat) mm/r;

Tool life:

Valve seat CBN blade: 800-1000 pcs

Catheter PCD reamer: 600-1000 pcs

Engine cylinder head valve seat and duct finishing

Material: Heat-resistant sintered steel and copper alloy

Cooling method: water-soluble cutting fluid

Processing standards: straightness, concentricity, surface roughness, roundness and runout

Fixture: Hydraulic Fixture

Tool: Non-standard Quick-Fit reamer with indexable insert

Blade 1: SOHW060202S, CBN 200

Reamer: PCD reamer Ø 5.00

Cutting parameters:

Vc: 100 m/min

f: 0.15 mm/tooth

Ap: 0.2 mm

Z: 1

Summary:

Tool life = 5000 plunge milling (CBN)

Tool life = 150000 holes (PCD reamer)

Minimize the amount of runout, improve the straightness and roundness of the pipe, the roundness of the valve seat and the quality of the entire part.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]