When use silicon carbide grinding wheel or other mixed-abrasive grinding wheels based on green silicon carbide for titanium alloy, the grinding wheel adheres to titanium alloy seriously, which leads to large grinding force and poor processing quality.

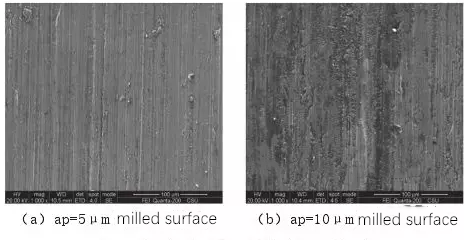

When the feed speed is 20mm/s and the grinding depth AP is 5μm, the plastic grooves and scratches formed by the grain extrusion appear on the surface of the workpiece in large quantities.

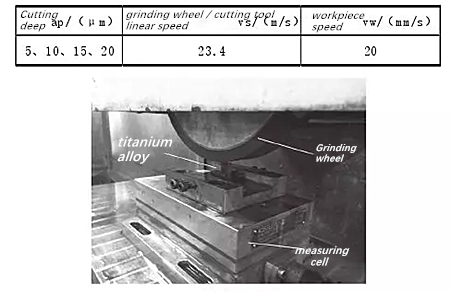

(This figure is the grinding milled surface by using SiC grinding wheel of titanium alloy)

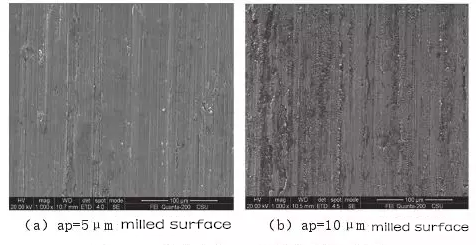

Although the surface quality will deteriorate with the increase of grinding depth, the grinding surface quality of CBN grinding wheel is obviously better.

This is because the heat dissipation in dry grinding is mainly completed through the grinding wheel, chip and workpiece, and the heat taken away by chip is very little due to the lack of chip generated in grinding, so the heat transfer characteristics of grinding wheel is the main factor affecting the grinding temperature.

(This figure is the grinding milled surface by using CBN grinding wheel of titanium alloy)

The surface quality of CBN grinding wheel is better than that of silicon carbide grinding wheel, and its machining surface integrity is better, and the macroscopic crack and surface damage are less. The roughness is also better than that of sic grinding wheel, and the contrast is more obvious when the grinding depth is increased.Compared with the ordinary sic wheels, the tangential force and normal force of CBN wheel are smaller. When the feed speed is 20mm/s and the cutting depth is 20μm, the tangential force and normal force of CBN wheel are reduced by 25.3% and 48.9% at the maximum.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]