Different components:

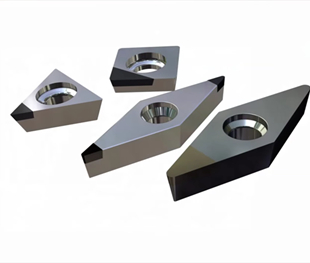

1. CBN insert: Artificial cubic boron nitride cutting tool, at high temperature can also maintain the characteristics of high hardness, mainly for processing iron parts.

2. Ceramic insert: Metals or nonmetals combined with oxygen (O), nitrogen (N), carbon (C), and other elements are called ceramics. After sintering, it can be used as a cutting tool.

Different classification:

1. CBN insert: Direct from the CBN single crystal sintered into PCBN, and add a certain proportion of binder PCBN sintered body two categories. There are two types, one is PCBN sintered block and another one is PCBN composite sintered with cemented carbide

2. Ceramic insert: It can be divided into metallic materials and nonmetallic materials. Nonmetallic materials are divided into inorganic materials and organic materials. Whatever the nature of the material, for example, melting point, hardness and electrical conductivity mainly depend on the internal microstructure, that is, depends on the combination mode and binding force of the internal particles.

Different use:

1. CBN insert: It is suitable for high speed cutting of cast iron, hardened steel and other materials.

2. Ceramic insert: Can be machined cast iron, heat resistant alloy, high hardness materials (quenched steel and chilled cast iron).

Characteristic:

1. CBN insert: It has the characteristics of high hardness, high wear resistance, high toughness, chemical inertia, red hardness, etc. Excellent cutting performance, can achieve stable cutting at high temperature, suitable for processing all kinds of hardened steel, tool steel, chilled cast iron and other difficult to machine materials. The cutting tool has the advantages of sharp cutting, good shape retention, high wear resistance, small wear per unit, few times of correction, and is conducive to automatic processing. It is suitable for all cutting processes from rough machining to fine machining.

2. Ceramic insert: Ceramic insert and metal friction is small, cutting is not easy to stick to the blade, and not easy to produce accumulation of debris. The tool's durability is several times than the traditional tool, which reduces the number of tool changes in the processing and ensures the small taper and high precision of the processed workpiece. Cutting efficiency is 3-10 times higher than traditional tools.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]