Diamond powder is mainly used for grinding and polishing, the control of particle size is particularly important. As long as there are oversized coarse particles will cause workpiece scratches so that preceding operation come to naught. So the quality inspection of powder is an important link to ensure the quality of powder products.

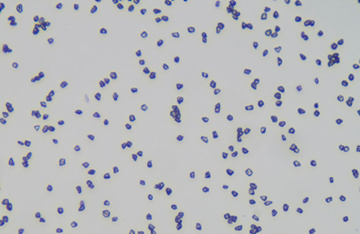

The picture below shows the fine powder of a certain particle size that we use well. We use this batch of fine powder to produce vitrified diamond grinding wheel, which has been received well received by America customers:

As can be seen from the picture, the proportion of the powder particles which are approximately spherical in shape is larger, the overall concentration is high, the particles are thick and the intensity is high. (Under the microscope observation, the high intensity powder has good transparency, its core transparent, surrounded by black edge outline. Low intensity powder: the whole is black. Flaky powder‘s intensity is low, fragile, but sharper). Particle size distribution: The width should also be as narrow as possible, because the wider the particle size composition, the larger the allowable size of large particles, it is easy to cause scratches.

We control the stability of raw materials through various testing instruments, including laser particle size analyzer, image particle analyzer, Raman, etc. And before using, every 5000 carats sample will be manually tested by metallographic microscope again to ensure the product stability of each batch of our grinding wheels. However, testing is only a means, which can not avoid various problems in our production. For example, for two different batches of diamond, as for the grinding wheel made in the previous batch, the customer experience is very good when using it , but the hardness of the material ring produced in the next batch may not meet the requirements due to shrinkage. There are also the same formula with the same pressure can not be pressed down at all. Even after the completion of the suppression will appear directly diagonal oblique crack. In order to fundamentally solve the problems caused by abrasive, diamond production factories need to control the quality of raw materials and more stable production process from the source and be truly responsible for the quality of their products.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]