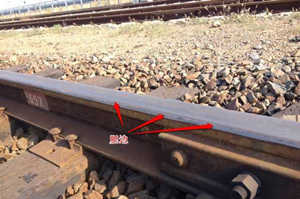

As a major part of rail transit, it is in direct contact with the wheel of the train, and its quality directly affects the safety and stability of the train. Under the influence of the dynamic action of the train, the natural environment and the quality of the track itself, the track will often be damaged, such as cracks, wear and other phenomena. In addition, the enormous pressure of millions of tons of trains moving across the track every year can easily cause the track to buckle and distort the contact surface with the wheels. And improper wheel-rail contact surface may bring negative effects on driving, such as fuel consumption, vibration noise, wheel wear, maintenance workload and cost increase, serious and even may lead to the destruction of the track and vehicle and the occurrence of driving accidents.

Special shape CBN grinding wheel, grinding efficiency increased 15 times, greatly save manpower, improve the grinding efficiency.

At present, the rail steel commonly used in China is a special wear-resistant steel, and Mn and Si are generally added in the main components of the production units. The purpose of adding Si is to change the fluidity of steel, play the role of solid solution strengthening, and improve the work hardening rate of steel. The purpose of adding Mn is to cooperate with carbon to ensure complete austenite structure and improve the work hardening rate of steel.

High manganese steel has austenite structure at room temperature, and there is no phase change during heating and cooling. At this time, the hardness of steel is very low, and the toughness is very high. When the steel is deformed by strong impact or strong pressure in the work, the surface layer has a strong deformation hardening, and also occurs martensite transformation, so that the hardness is significantly improved, and the heart is still maintained as the original high toughness state.

Therefore, the high wear resistance of this kind of steel can not be played out in the case of small force in the work. That is to say, in the processing of this kind of products with common grinding wheel, which is widely used in China, the strong grinding in order to improve the efficiency instead increases the wear resistance of the processed object.

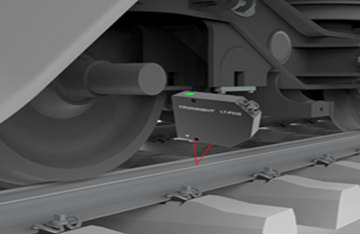

Working principle of rail Grinding car Rail grinding is mainly through the grinding machine or grinding train on the top of the rolling surface of the rail. With highest efficiency, the most widely used steel rail grinding cars, for example: the train drive polishing machine travel on the railway tracks at a walking speed, forming grinding head and the tracks between the relative feed movement of the grinding machine standing vertically and direct drive grinding wheel rotation, as well as the grinding head down a certain pressure and different grinding Angle, a one-time to track each interface grind and polish.

Based on the actual processing situation and considering the reason that the shape of the rail is convenient for processing, the shape of the grinding wheel should be convenient for the processing and grinding of the railway crossing. Therefore, CBN is used as abrasive to make bowl grinding wheel with thinner thickness. It is very important to choose the binder of CBN grinding wheel because of the limitation of processing requirement, processing object and processing environment. Metal binder has long life but low efficiency; Resin binders are more efficient and more suitable for efficient working environments. The resin binder should be used as the binder for grinding the rail grinding wheel. The grain size of CBN grinding wheel is 100/12, the concentration is 75%, and the matrix of the grinding wheel is aluminum.

Conclusion:

1.CBN grinding wheel is feasible in the field of processing the fat edge of railway track, which can improve the processing efficiency by 15 ~ 20 times;

2. Coolant must be used for CBN grinding wheel to process fat edge of rail;

3.CBN grinding wheel can greatly reduce the physical labor and reduce the comprehensive consumption cost;

4. It is a new application field for CBN grinding wheel to process railroad fat edge, which has a very broad market.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]