Under normal circumstances, the brake discs should be replaced every 60,000 to 80,000 kilometers. Brake discs are vulnerable parts in the car's braking system. As the mileage of the car increases, the brake discs will continue to wear. When the brake disc is worn to a certain degree, it needs to be replaced. The demand for replacement and machining of brake discs each year increases with the increase in the number of cars. It is not difficult to machine itself, but how to make the cutting process more efficient and improve the efficiency of production while ensuring its surface quality and dimensional accuracy. Much depends on the choice of tool.

The material of common brake discs is HT250, with three main components (ratio): C: 3.1-3.4 Si: 1.9-2.3 Mn: 0.6-0.9. Mechanical performance requirements: tensile strength>=206MPa, bending strength>=1000MPa, deflection>=5.1mm, hardness requirements between: 187-241HB. The processing of this type of material puts forward a very high requirement on the wear resistance of the processing tool. Due to the actual braking effect of the brake, the surface finish of the brake disc processing does not need to be too high, generally reaching Ra3.2μm.

In response to the above common processing conditions, Moresuperhard has customized CBN tool materials. Compared with cemented carbide, CBN materials have great advantages in processing efficiency, tool life, and quality and size of parts. Compared with other brands of CBN tools, Moresuperhard tool have a very high cost performance and stability, and provide corresponding grinding services, which can effectively reduce customers' use costs and single-piece processing costs.

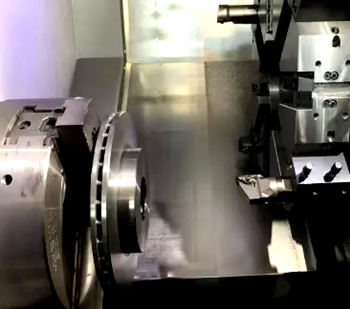

Our tool is tested at a customer. The customer uses a horizontal lathe to process the brake disc. The material is HT250, the workpiece hardness is about HRC30, the diameter of the inner hole is D140, the diameter of the outer circle is D280, and the processing surface requires Ra3. 2μm.

---EDITOR: Miya Ma

----POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]