CVD diamond are widely use in semiconductors, optics and thermics industry because its outstanding physical and chemical properties, which called "ultimate semiconductor material". there are high requirement when as semiconductor substrate material,it means the ultra-precision polishing becomes the key link determining its performance and application.Chemical mechanical polishing (CMP), with its unique advantages, has become the core technology for ultra-precision processing of CVD single-crystal diamond.

Diamond polishing technology

The main existing polishing methods include mechanical polishing, thermal chemical polishing, laser polishing, and ion beam polishing.

CMP with unique advantages compared with the above methods, The equipment has low operating costs and does not require high-energy laser sources or complex ion beam generating devices; the process is relatively simple and easy to operate and control; the surface damage after polishing is small, which can effectively avoid scratches, cracks and other defects in mechanical polishing, and meet the requirements of CVD single-crystal diamond for ultra-smooth and low-damage surfaces.

Polishing discs

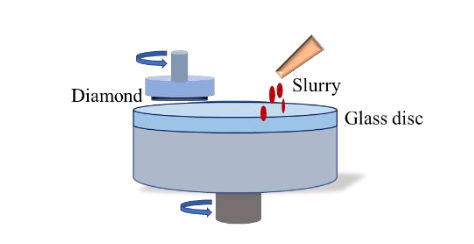

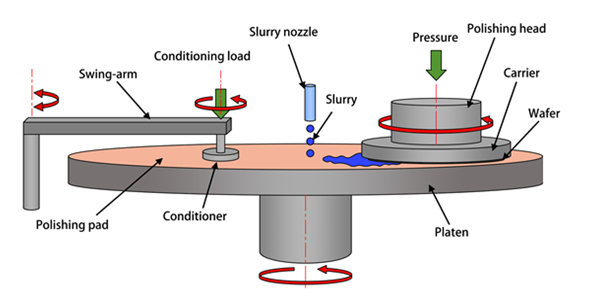

The material, hardness and surface structure of the polishing disc have a significant impact on the CMP process. The material should have good wear resistance and chemical stability. Commonly used materials include cast iron discs, glass discs, ceramic discs and polishing pads. Cast iron discs have high hardness and a high initial removal rate, but may cause changes in surface roughness due to wear; glass discs have a smooth surface, which is conducive to obtaining a smooth surface and is often used for fine processing; ceramic discs have a certain hardness and chemical stability; polishing pads have good elasticity and liquid-carrying capacity, which can evenly distribute the polishing liquid and abrasive particles, reducing surface scratches. The hardness and surface structure of the polishing disc determine its grip on abrasive particles and the grinding method on the diamond surface, thereby affecting the material removal rate and surface quality.

Rotational speed of the polishing disc

The rotational speed of the polishing disc determines the relative movement speed between the abrasive particles and the diamond surface, which affects the material removal rate and surface quality. If the rotational speed is too fast, it may cause excessive impact of the abrasive particles on the surface, resulting in surface damage; if the rotational speed is too slow, the removal rate will be low. Generally, a higher rotational speed (such as 50 - 80 r/min) can be used during rough processing to improve the removal efficiency, while a lower rotational speed (such as 30 - 50 r/min) should be adopted during fine processing to ensure a smooth surface. At the same time, the rotational speed of the polishing disc also needs to be coordinated with parameters such as polishing pressure and abrasive particle size to achieve the best polishing effect.

Application Cases of CMP Technology

1. Semiconductor Substrate Preparation

In the semiconductor field, a company uses CMP technology to polish CVD single-crystal diamond to produce high-quality semiconductor substrates. By optimizing polishing process parameters, selecting a polishing slurry composed of H₂O₂ and Fe²⁺, using diamond abrasives of a specific particle size, and glass polishing pads, and maintaining appropriate polishing pressure, rotation speed, and temperature, the company successfully reduced the surface roughness of the diamond substrate to below 0.5nm, meeting the stringent surface quality requirements for subsequent epitaxial growth.

2. Optical Component Processing

An optical component manufacturer uses CMP technology for ultra-precision polishing of CVD single-crystal diamond optical lenses. Using a polishing slurry containing KMnO₄ as an oxidant and a special surfactant, combined with ceramic polishing pads, the company achieved surface roughness of less than 1nm and a surface accuracy of λ/20 (λ being the operating wavelength) through rough and fine polishing steps. Optical lenses processed using this CMP process demonstrate high light transmittance, low scattering loss, and clear imaging in optical performance tests, making them widely used in high-end optical instruments.

3. Thermal Management Material Processing

In the field of thermal management materials, a company performed CMP processing on CVD single-crystal diamond heat sinks. By adjusting the polishing process, using a polishing slurry containing specific abrasives and additives, and optimizing polishing pressure and speed, the surface roughness of the heat sink was reduced to approximately 2nm, significantly improving the thermal contact performance between the heat sink and other materials.

---EDITOR: Doris Hu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]