In modern automotive manufacturing, achieving both high performance and lightweight design is a major engineering goal. Aluminum alloys, especially high-silicon aluminum alloys, have become the preferred material for engine cylinder blocks due to their low density, excellent thermal conductivity, and good wear resistance. However, these materials also pose significant machining challenges due to their hardness and abrasive nature caused by the presence of hard silicon particles.

To meet the increasingly stringent requirements for dimensional accuracy, surface roughness, and tool life, polycrystalline diamond (PCD) cutting tools have become the most effective solution for precision boring and finishing of high-silicon aluminum alloy cylinder bores. This article explores the application of PCD cutting tools in precision boring of high-silicon aluminum alloy cylinder blocks, including material characteristics, machining difficulties, tool selection, process optimization, and performance advantages.

The use of PCD cutting tools in precision boring of high-silicon aluminum alloy automotive cylinder blocks represents a significant advancement in modern engine manufacturing. PCD tools provide the ideal combination of wear resistance, accuracy, and surface quality required for mass production.

Characteristics of High-Silicon Aluminum Alloys

High-silicon aluminum alloys typically contain 12–25% silicon (Si), sometimes even more in specific automotive applications such as AlSi17Cu4Mg. Silicon, being extremely hard (about 1200 HV), provides excellent wear resistance to the alloy, but also creates severe abrasion during machining.

Key characteristics include:

-Lightweight: About one-third the density of steel, significantly reducing engine weight.

-High thermal conductivity: Facilitates heat dissipation, improving engine efficiency.

-Low thermal expansion: Maintains dimensional stability at elevated temperatures.

-Hard and abrasive microstructure: Silicon particles embedded in the aluminum matrix create high tool wear.

Because of these properties, conventional carbide tools wear rapidly when machining high-silicon aluminum alloys, resulting in poor surface finish and dimensional inaccuracy. This is where PCD tools demonstrate their superiority.

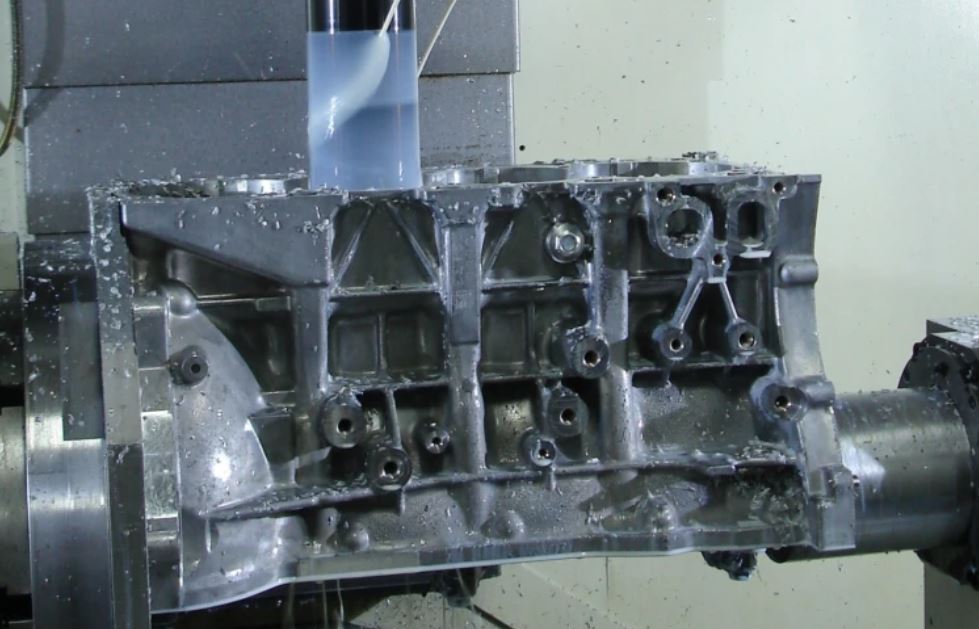

High-silicon aluminum alloy cylinder blocks (with a silicon content of 10%-12%) are core components of automotive engine powertrains. Subjected to high-temperature and high-pressure operating conditions, their cylinder bores have extremely strict requirements for boring precision, surface quality, and machining stability. In traditional machining processes, cemented carbide tools struggle to balance efficiency and quality due to abrasive wear caused by silicon particles in the high-silicon aluminum alloy, becoming a bottleneck in mass production.

The cylinder bore is one of the most critical components in an engine. It directly affects combustion efficiency, oil consumption, and overall engine performance. Machining it requires high accuracy (IT6–IT7) and surface roughness Ra ≤ 0.4 μm.

Key machining challenges include:

Severe Tool Wear:

Silicon particles act as micro-cutters that abrade the cutting edge, causing flank wear and micro-chipping of conventional carbide tools.

Built-Up Edge (BUE) Formation:

Aluminum tends to adhere to the cutting edge, especially under improper cutting temperatures or feed rates, degrading surface quality.

Dimensional Stability Issues:

Heat generation during cutting can cause thermal expansion of both the tool and workpiece, affecting bore geometry and roundness.

Surface Integrity Requirements:

Cylinder bores require an extremely smooth surface to ensure proper oil retention and sealing performance. Micro-scratches or tearing from dull tools are unacceptable.

To overcome these problems, manufacturers increasingly turn to PCD cutting tools, which maintain edge sharpness and provide excellent thermal and wear resistance.

Polycrystalline diamond (PCD) is a synthetic material composed of fine diamond grains sintered under high temperature and pressure. It exhibits extreme hardness (8000–9000 HV) and outstanding thermal conductivity (400–700 W/m·K). When used as a cutting tool material, it offers the following advantages:

Outstanding Wear Resistance:

The diamond structure resists abrasion from hard silicon particles, extending tool life several times longer than carbide or cermet tools.

Superior Surface Finish:

The sharp cutting edge and low friction coefficient of PCD minimize BUE and tearing, producing a mirror-like surface on the bore.

Excellent Dimensional Accuracy:

Low cutting forces and minimal tool deformation ensure tight tolerances, crucial for bore concentricity and cylindricity.

High Productivity:

PCD tools allow higher cutting speeds (up to 800–1500 m/min) and feed rates, significantly improving machining efficiency.

Stable Performance and Consistency:

PCD maintains sharpness and cutting performance over long production runs, ensuring consistency in mass production.

Structure and Design of PCD Boring Tools

PCD precision boring tools for high-silicon aluminum cylinder blocks are typically modular or multi-blade designs, adapted for CNC machining centers or specialized boring machines.

Key design features:

Tool Body Material: High-stiffness steel or lightweight aluminum alloy with vibration damping.

PCD Tip Geometry: Fine-grain PCD inserts brazed or mechanically clamped, with optimized rake and clearance angles.

Number of Cutting Edges: Multi-edge design (often 4–8 edges) for simultaneous machining and balanced cutting load.

Adjustable Cutting Edges: For achieving precise bore diameter control (±2 μm).

Integrated Coolant Holes: Internal coolant supply to effectively remove chips and control cutting temperature.

A two-step boring process is often used:

Rough Boring: Removes the majority of material with carbide tools or rough PCD inserts.

Finish Boring: Uses high-precision PCD tools to achieve final size and surface quality.

1.Severe tool wear: Hard silicon particles (with a hardness of HV800-1000) in the high-silicon aluminum alloy rapidly wear down the cutting edges of traditional cemented carbide tools. A single tool can only machine 500-800 cylinder blocks before requiring replacement, leading to high tool change frequency and frequent dimensional fluctuations.

2.Precision non-compliance: The cylinder bore design requires a roundness of ≤0.008 mm and cylindricity of ≤0.01 mm. After machining with traditional tools, "bell-mouth" deformation often occurs due to cutting edge wear, resulting in a pass rate of only 85%-90%.

3. Insufficient surface quality: The industry requires a cylinder bore surface roughness (Ra) of ≤0.2 μm to ensure piston sealing. However, the Ra value after machining with traditional tools typically ranges from 0.3-0.5 μm, necessitating an additional polishing process.

4. Risk of thermal deformation: Cemented carbide tools operate at low cutting speeds (80-100 m/min), and prolonged machining causes local temperature rise of the cylinder block (exceeding 40°C), leading to micro-deformation.

By introducing PCD (Polycrystalline Diamond) cutting tools to replace traditional cemented carbide tools and optimizing machining processes, the challenges in boring high-silicon aluminum alloy cylinder blocks are resolved as follows:

1.Customized Tool Design - Fine-grain PCD inserts (8-12 μm grain size, hardness of HV9000-10000) are selected, offering 15-20 times higher resistance to abrasive wear than cemented carbide. - The tool body adopts a cemented carbide substrate + vacuum brazing process to ensure the bonding strength between the PCD insert and substrate (shear strength ≥150 MPa). - The cutting edge undergoes 0.01-0.02 mm passivation treatment to prevent edge chipping during high-speed cutting and reduce surface roughness.

2.Machining Parameter Optimization - The cutting speed is increased to 150-200 m/min (1.8-2 times that of cemented carbide tools), with a feed rate controlled at 0.1-0.15 mm/r and a cutting depth of 0.2-0.5 mm, reducing the contact time between silicon particles and the cutting edge. - A three-stage machining path ("rough boring - semi-finish boring - finish boring") is adopted: rough boring removes 2-3 mm of stock, while finish boring uses a single-pass cutting depth of ≤0.1 mm to ensure dimensional precision.

3.Cooling System Upgrade

A 3-5 MPa high-pressure internal cooling system is configured. Coolant (water-based emulsion with 8%-10% concentration) is delivered directly to the cutting zone through internal cooling holes in the tool, controlling the machining temperature rise within 25°C and avoiding high-temperature oxidation of PCD (PCD oxidation temperature ≥700°C, making this temperature range safe and controllable).

The coolant filtration precision is improved to 5 μm to prevent impurities from scratching the cylinder bore surface.

1.Rough Machining Stage

PCD rough boring tools are used to remove the casting stock of cylinder bores. The focus is on maintaining stable cutting force (≤300 N) to avoid cylinder block deformation due to uneven force. A 0.3-0.5 mm finish machining allowance is reserved for the cylinder bore diameter after roughing.

2.Finish Machining Stage

PCD finish boring tools are used for dimensional calibration. Real-time compensation (compensation precision of ±0.001 mm) via the CNC system ensures the cylinder bore diameter tolerance is controlled within ±0.003 mm.

3.Post-Machining Inspection Stage

A coordinate measuring machine (CMM, measurement precision of ±0.0005 mm) is used to inspect cylinder bore roundness and cylindricity. 10 pieces are sampled per batch, with acceptance criteria of roundness ≤0.005 mm and cylindricity ≤0.008 mm.

A surface roughness tester (resolution of 0.001 μm) is used to inspect the inner wall of the cylinder bore, requiring Ra ≤0.1 μm.

An air tightness test is conducted (test pressure of 0.5 MPa, pressure holding time of 30 s), with a leakage rate ≤5 mL/min to ensure the sealing performance of the cylinder block.

Results and Benefits

1.Significantly extended tool life: A single PCD tool can machine 4000-5000 cylinder blocks, representing a 5-8 times lifespan increase compared to cemented carbide tools. Tool changes are reduced from 8-10 times per day to 1-2 times, cutting equipment downtime by 60%.

2. Substantial machining cost reduction: Although PCD tools cost 3-4 times more than cemented carbide tools, the tool cost per cylinder block is reduced from 12 RMB to 9 RMB (a 25% decrease). Additionally, the polishing process is eliminated, shortening the machining time per piece from 120 seconds to 85 seconds and increasing production capacity by 29%.

3. Comprehensive product quality improvement: The cylinder bore machining pass rate rises from 88% to 99.5%, with surface roughness stably maintained at Ra 0.08-0.1 μm and roundness ≤0.004 mm. This meets the "honing-free" process requirements of high-end engines (traditional processes require 15-20 minutes of honing).

4. Enhanced production stability: The machining dimensional fluctuation range is reduced from ±0.01 mm to ±0.003 mm, and the production line’s Overall Equipment Efficiency (OEE) increases from 75% to 92%, minimizing rework waste caused by dimensional deviations.

Conclusion

In the precision boring of high-silicon aluminum alloy automotive cylinder blocks, PCD cutting tools, with their excellent abrasive wear resistance and machining stability, not only address the pain points of traditional cemented carbide tools (short lifespan, poor precision, low efficiency) but also achieve multiple goals of cost reduction, quality improvement, and efficiency enhancement through process optimization. This application case provides a replicable technical solution for the precision machining of high-hardness, high-wear-resistant materials in the automotive parts industry, and is particularly suitable for mass production scenarios of engines with an annual output of over 100,000 units.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]