Optimum solution for high-speed turning of high-temperature alloys

CNGN, RCGX, RPGN, SNGN

Maching: high-speed cutting, heavy-duty cutting, and interrupted cutting operations

Material: cast iron and nickel-based superalloys

Sialon ceramic (a solid solution of Si₃N₄-Al₂O₃) is a high-performance cutting tool material with excellent properties including high hardness (≥1800 HV), high temperature resistance (≥1300 °C), wear and corrosion resistance.

SiAlON ceramic cutting tools with high aluminum content are particularly effective when machining nickel-based superalloys (such as Inconel 718, Rene, Hastelloy, and Waspaloy).

SiAlON ceramic inserts are suitable for turning and milling operations, including roughing, semi-finishing, and finishing, as well as interrupted cutting.The axial depth of cut (ap) is up to 0.197 in. (5 mm). The ceramic indexable inserts with chamfer have a rounded cutting edge (hone E) for a soft cutting action or a tough cutting edge (T-land T01020) for heavy-duty machining.

Sialon ceramic cutting tools are particularly suitable for high-speed cutting, heavy-duty cutting, and interrupted cutting operations. They are an ideal choice for high-speed dry machining of cast iron and nickel-based superalloys, and have been widely used in high-end manufacturing fields such as aerospace and automotive industries.

1. Ultra-high Hardness and Wear Resistance

With a hardness of HRA 93-95 (equivalent to HV 1800-2200), it is significantly higher than that of cemented carbide cutting tools (HRA 89-92) and close to the level of cubic boron nitride (CBN). Reinforced by the strong covalent bond framework of Si₃N₄ and Al₂O₃ solid solution, it forms a dense microstructure, which improves the abrasive wear resistance by 5-10 times and reduces the flank wear rate of the tool by more than 50%. It maintains the sharpness of the tool edge and extends the service life by 3-8 times.

2. Excellent Thermal Stability

Its heat resistance temperature can reach above 1300℃, with better oxidation resistance than traditional Al₂O₃ ceramics. It can still maintain good mechanical properties at high temperatures without easy softening and deformation, and is suitable for high-temperature cutting environments such as high-speed cutting and dry cutting.

3. High Strength and Toughness

The flexural strength of Sialon ceramic cutting tools can reach 1200MPa, and the "self-toughening" effect is achieved through the interwoven structure of β-Si₃N₄ columnar crystals, with a KIC value of 6-8MPa·m¹/² (only 3-4MPa·m¹/² for traditional ceramics). It can withstand the impact load of interrupted cutting, and its chipping resistance is 3 times higher than that of Al₂O₃ ceramics.

4. Superb Thermal Shock Resistance

Sialon ceramic has an extremely low thermal expansion coefficient (about 2.8-3.2×10⁻⁶/℃), which is much lower than that of machined metal materials such as cast iron. This characteristic enables Sialon ceramic cutting tools to effectively reduce thermal stress when facing abrupt temperature changes during the cutting process, thereby resisting thermal shock and reducing the generation of cracks.

Leveraging the advantages of high hardness, excellent wear resistance, high-temperature chemical stability and low affinity, Sialon ceramic cutting tools are suitable for high-efficiency and high-precision cutting of difficult-to-machine materials. The specific application scenarios are classified as follows:

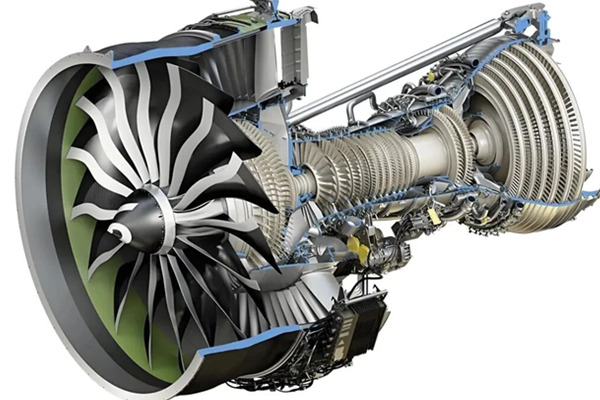

High-speed Cutting of Nickel-based Superalloys (Core Application Scenario)

Machining Workpieces | Inconel 718, Hastelloy C276, GH4169 and other series of nickel-based superalloys |

Typical Components | Turbine disks, turbine blades and combustion chamber components of aero-engines; hot-end parts such as rotors and stators of gas turbines |

Machining Conditions | Roughing/semi-finishing, high-speed dry cutting or minimum quantity lubrication (MQL) cutting (cutting speed: 300~800m/min) |

It replaces traditional cemented carbides with slow tool wear, and the machining efficiency can be improved by 8-10 times without adhesive wear. The tool life is usually 5-8 times that of cemented carbides. Its high-temperature oxidation resistance makes it perfectly suitable for the mass precision production of hot-end parts of high-end equipment in the aerospace and energy fields. | |

High-Speed Dry Cutting of Cast Iron Materials (High-Efficiency Substitution Scenario)

Machining Workpieces | Wear-resistant cast irons including gray cast iron (HT200/HT300), ductile iron (QT450/QT600), and compacted graphite iron |

Typical Components | Auto engine blocks/cylinder heads, brake discs/drums, machine tool beds, diesel engine cylinder liners, etc |

Machining Conditions | Roughing/semi-finishing, high-speed dry cutting (cutting speed: 800~1500m/min). |

It replaces coated cemented carbides with excellent thermal shock resistance, and the graphite phase enables self-lubrication and wear reduction. The tool life is usually 5-10 times that of coated cemented carbides, and the cutting speed can be increased by 3-5 times. Without cutting fluid pollution, it is suitable for assembly line mass production in the automotive, machine tool and other industries. | |

Machining Tests of Sialon Ceramics

Turning Test for Superalloys

Workpiece | GH4169 bar, nickel-based superalloy (equivalent to Inconel 718) |

Parameters | ap=1mm, f=0.15mm/rev, Vc=250m/min |

End Milling of Superalloy Blades

Workpiece | Aero-engine blade, nickel-based superalloy (Inconel 718) |

Parameters | Dc=35mm, ap=1mm, ae=5~15mm, fz=0.13mm/t, Vc=928m/min, n=11400r/min |

Insert | RPGN0903E040 |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]