What is PCD?

Polycrystalline Diamond (PCD) is a new type of superhard material that has been researched and used internationally since the 1970s. It is formed by sintering at a high temperature of 1400°C and a high pressure of 6GPa.

Difficulties in PCD processing

Due to its high hardness, PCD material is easy to produce high temperature in the processing process, and the high hardness also leads to poor grinding efficiency, so it is really a difficult material to grind.

PCD grinding solution

Abrasive selection:

In order to process PCD materials, abrasive of higher hardness should be selected, so only super abrasive grinding wheel with diamond or CBN abrasive can be selected.

Bond selection:

However, Superabrasive grinding wheels are mostly resin bond , but Vitrified bond are more suitable for PCD materials.Because Vitrified bond sintering can produce more pores, and Vitrified good heat resistance, cutting sharp, so it is not easy to heat and expansion.

When grinding with high hardness, the grinding efficiency and precision will be higher than ordinary resin diamond grinding wheel.Therefore, when processing PCD materials, the most appropriate choice is to use Vitrified bond grinding wheel.

Product Recommendations

Vitrified diamond grinding wheels for PCD & PCBN tools

It is suitable for rough, medium, fine and super fine grinding of PCD/CBN tools. In addition to grinding PCD/PCBN/Monocrystal standard tools, it can also grind PCD milling cutters, reamers, and other customized tools.

Advantages:

1. The porous structure of the abrasive layer makes the passivated diamond fall off faster, which can prevent vertical stripes on the workpiece and improve the surface quality

2. Perfect dimensional tolerance control, applicable to CNC and manual grinder

3. Good self-sharpening, high grinding efficiency, high wear resistance, low abrasive consumption

4. The use of Vitrified bond can make pcd/cbn tools to achieve a good surface finish and avoid cutting edge chipping, thereby reducing the scrap rate and improving the accuracy of Pcd/cbn tools

5. The service life of the Vitrified bond grinding wheel is more than 10 times that of the resin bond grinding wheel, and can realize easy online dressing

Specifications

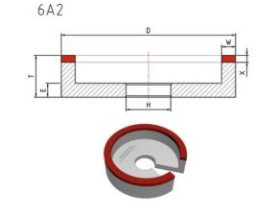

Type | D(mm) | T(mm) | H(mm) | W(mm) | X(mm) |

6A2 | 100 | 40 | 32/40 | 1-20 | 5-10 |

125 | 40 | 32/40 | 1-20 | 5-10 | |

150 | 40 | 32/40 | 1-20 | 5-10 | |

Other wheel sizes can be customized Suitable for all kinds of tool grinders: EWAG 、Coborn、Vollmer、Agathon、MAKINO、WAIDA、MYTECH | |||||

Common grit and specifications

Rough grinding

| W40(D35), W28(D20) | Excellent grinding force, mostly used for rough blade grinding, high surface material removal rate. |

Middle grinding

| W20(D20) | Both material removal rate and surface quality are considered. |

Fine grinding

| W10(D15A), W7(D15B) | It is mostly used for blade fine grinding, with excellent surface quality and no chipping on the cutting edge. |

Super fine grinding | W5(D7), W3.5(D3) | Pursue the ultimate surface and cutting edge quality. |

Specifications can be customized according to actual needs | ||

Dresser recommendation

Special dressing wheel for ceramic diamond grinding wheel. The same use of Vitrified bond, efficiency and life is 50 times that of ordinary alumina dressing wheels.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]