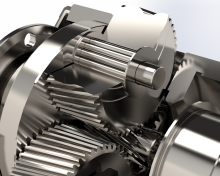

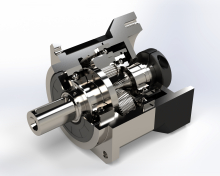

1. The advantages of spur gear and transmission:simple manufacture, easy assembly, direct engagement without synchronizer, and direct use of deep groove ball bearings for shaft end installation, basically without axial force.

The disadvantage of spur gear and transmission:the straight gear transmission stability is poor, easy to produce impact, vibration and noise. Therefore, it is not suitable for high-speed and heavy duty occasions.

2. Helical gear and transmission advantages: the helical gear meshing is gradually carried out, the tooth contact degree is large (effective meshing teeth), the load is not suddenly added or removed, so the transmission is stable, low noise, long service life, widely used in high speed and heavy duty occasions.

The disadvantage of helical gear and transmission: when manufacturing is slightly complex, there is a lot of axial force at work, which is adverse to bearings.

Therefore, the first gear and reverse gear of the automobile gearbox are used for economy and compactness because they do not work for a long time and the speed is not high. While the other gears and rear axle have high requirements for smoothness because of high-speed operation, so the helical gear is used. In order to reduce the influence of axial force, the gear tooth rotation offset and the manufacturing process of modified gear are adopted, so that the tooth profile with taper can reduce the bearing capacity and maintain smooth operation.

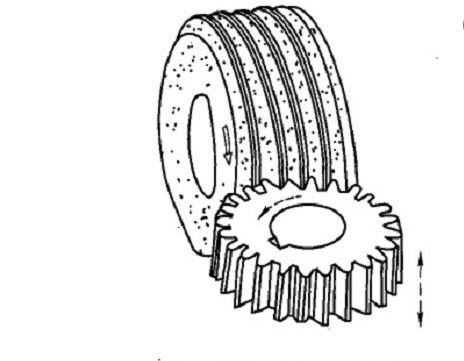

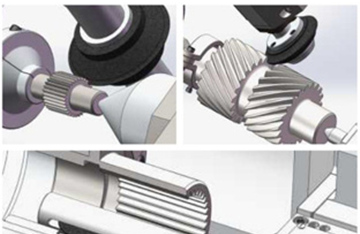

As the core technology equipment of high precision and hard tooth surface gear processing, the application of gear grinding machine is becoming more and more popular. Generally speaking, tooth grinding is the tooth shape finishing process of gear parts. It is a tooth shape finishing process which removes the finishing allowance on the basis of completing the rough machining of tooth shape (such as hobbing and milling tooth etc.) and heat treatment, so as to further improve the precision and surface quality of gear. Due to the special shape of gear parts, it is necessary to ensure that the initial entering position of grinding wheel is aligned with the tooth groove of the gear blank during grinding, that is to say, the gear groove to be grinded must be circumferential positioning (tooth alignment).

Influence of tooth precision on tooth profile grinding:

In order to ensure that the grinding wheel enters the tooth groove correctly and equalize the grinding allowance of left and right tooth surfaces, the gear grinding machine needs to carry out circumferential positioning of the parts before grinding them.

It is necessary to ensure that the center surface of tooth groove coincides with the center surface of sand gear tooth profile. After correctly grinding the first tooth groove, the machine tool will in turn separate the workpiece teeth and grind out all tooth shapes.

As can be seen from Figure 1: if the circumferential positioning of the workpiece is not accurate before grinding, the size of the grinding amount on both sides of the tooth groove will be uneven. Serious grinding wheels will directly impact the tooth surface and grind the workpiece into waste or even cause the loss of precision of the machine tool.

The circumferential positioning deviation will directly affect the tooth margin of subsequent grinding, so the actual grinding must be considered according to the side with the large margin, resulting in the increase of radial feed times, thus reducing the machining efficiency.

In addition, the uneven allowance will cause allowance on one side of the actual grinding layer thickness is greater than the theoretical value, for carburizing or nitriding heat treatment of hard tooth surface gear, because the surface hardening layer is very shallow, actual grinding thickness increase will lead to the finished parts of tooth surface hardness decreased, resulting in parts quality problem or affect the parts performance.

Grinding wheel selection:

The selection of grinding wheel mainly considers abrasive, particle size, hardness, bonding agent and so on.

Abrasive: grinding wheel abrasive selection is mainly related to the material and heat treatment method, hardness. The grinding wheel should have high hardness, wear resistance, heat resistance and toughness, as well as sharp corners for cutting metal.

Super hard abrasive: mainly natural diamond, artificial diamond, cubic boron nitride, etc., general grinding of high hardness, brittle materials. At the same time, diamond abrasives can also be used as grinding wheel dressing tools.

Corundum and ceramic abrasives are recommended for carburizing and hardening gear tooth surface grinding.

Particle size: Particle size refers to the size of grinding wheel grain size. The smaller the size of grinding wheel grain size is, the smaller the particle size is. On the contrary, the larger the particle size brand. The selection of grinding wheel size is directly related to the machining time and the roughness of tooth surface during gear grinding.

Application conditions of coarse grain grinding wheel:

Coarse-grained grinding wheels are selected for grinding under the following conditions:

(1) parts with high toughness and low hardness.

(2) materials with poor thermal conductivity and easy to burn.

(3) When the feed quantity is large.

(4) When the roughness of the tooth surface is not high, that is, on the premise of meeting the roughness requirements, coarse-grained grinding wheels should be selected as far as possible.

(5) When the contact area between tooth surface and grinding is large, the grinding wheel with larger particle size should be selected to prevent excessive heat generated during grinding from grinding burns.

Fine grain grinding wheel applicable conditions:

Under the following circumstances, a finer grain grinding wheel is selected for grinding:

(1) During tooth surface grinding, the retention of forming wheel is improved to ensure higher grinding tooth precision.

(2) when the roughness of tooth surface is higher.

(3) Grinding parts with smaller tooth surface modulus.

The grinding wheel with the grain size of 46~80 should be selected for the carburized and hardened gear during grinding, which can increase the contact area between grinding wheel and tooth surface and reduce the roughness of tooth surface. At the same time, the grinding wheel should have a certain chip tolerance space to ensure chip removal and heat dissipation performance.

Hardness: The hardness of grinding wheel refers to the degree of difficulty for grinding grains on the surface of grinding wheel to break or fall off from bond under the action of axial and radial force of machine tool when the grinding wheel rotates at a high speed during gear grinding. The general principle for selecting soft grinding wheel is as follows:

(1) In order to increase the grinding contact area, soft grinding wheel can be used to process gears with low hardness.

(2) For tooth surfaces with low thermal conductivity and material sensitivity to thermal temperature, soft grinding wheel is selected.

(3) When the linear speed of grinding wheel is high, soft grinding wheel is used.

(4) In order to improve grinding efficiency, soft grinding wheel can be selected.

The general principle for selecting hard grinding wheel is as follows:

(1) When the grinding tooth surface is in discontinuous state, a hard grinding wheel should be selected.

(2) In order to maintain better grinding accuracy, hard grinding wheel was selected. When carburizing and hardening gears are grinding, the grinding wheel with medium hardness is selected.

Bonding agent: bonding agent is the abrasive material bonded together. The strength, impact resistance and heat resistance of grinding wheel mainly depend on the type and nature of bonding agent of grinding wheel.

For carburized and hardened gear grinding, the grinding wheel with ceramic bond should be selected.

----EDITOR:Doris Hu

----POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]