A PDC cutter is a cutting element made by sintering polycrystalline diamond (PCD) powder on a tungsten carbide substrate under high pressure and high temperature (HPHT). The diamond layer provides extreme hardness, while the carbide substrate offers toughness and support.

Key Features

-Extremely high hardness (second only to natural diamond)

-Excellent wear resistance-High thermal stability

-Strong impact toughness

-Long service life in abrasive formations

PDC cutters are typically mounted on PDC drill bits, reamers, hole openers, and coal mining bits, enabling highly efficient shearing and scraping cutting action.

PDC cutters are available in multiple shapes, each engineered to handle specific formation challenges and drilling requirements. The geometry of the cutter influences cutting aggressiveness, impact resistance, heat dissipation, and overall drilling performance. Below are the most commonly used and industry-recognized PDC cutter shapes:

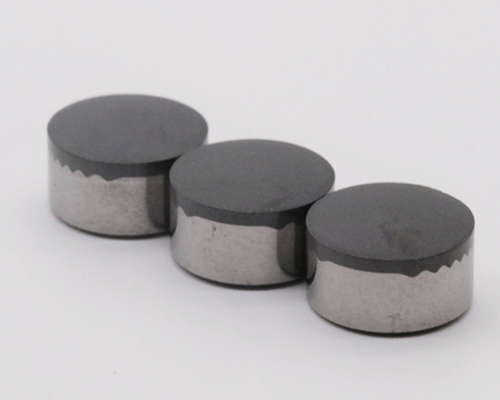

1. Flat PDC Cutter (Standard Flat Face)

Description:

A traditional cylindrical PDC cutter with a completely flat diamond table.

Features:

-Smooth and stable cutting action

Low friction, high ROP in softer formations

Simple structure and cost-effective

Best For:

-Soft to medium formations

-Shale, limestone, soft sandstone

-General drilling operations

Description:

The diamond surface is curved into a dome or convex shape.

Features:

Very high impact resistance

Strong anti-chipping and anti-breakage performance

Better heat dissipation than flat cutters

Long life in abrasive formations

Best For:

-Hard and abrasive formations

-Deep-well drilling

-Interbedded formations with strong impacts

3. Conical PDC Cutter (Pointed Cone Shape)

Description:

Featuring a pointed or cone-shaped diamond face that concentrates force into a small contact area.

Features:

* Extremely aggressive cutting ability

* Faster initiation of rock fracture

* Performs well in brittle, hard formations

Best For:

-Ultra-hard rocks like granite

-Percussive or hybrid drilling bits

-Hard interbedded rock layers

4. Helmet-Shaped PDC Cutter (Half-Dome / Shield Cutter)

4. Helmet-Shaped PDC Cutter (Half-Dome / Shield Cutter)

Description:

A specialized cutter featuring a dome front + flat or tapered rear, resembling a helmet profile.

Features:

Combines durability (front dome) with aggressive cutting (rear edge)

Excellent balance between wear resistance and ROP

Strong resistance against impact and cutter breakage

Stable drilling in complex strata

Best For:

Hard and highly abrasive formations

Deep drilling with high temperature and pressure

Unstable formations requiring both strength and cutting efficiency

PDC Cutter Shape | Geometry / Description | Key Features | Ideal Formation |

Flat | Flat diamond face | Smooth cutting, stable, high ROP | Soft–medium rock (shale, limestone, soft sandstone) |

Dome / Convex | Curved diamond surface | High impact resistance, anti-chipping, long life | Hard, abrasive rock, interbedded formations |

Conical | Pointed cone-shaped face | Aggressive cutting, initiates fractures easily | Ultra-hard, brittle rock (granite, hard interbedded layers) |

Helmet-Shaped | Dome front + flat/tapered rear | Balanced durability and cutting, strong anti-breakage | Deep, complex, and highly abrasive formations |

When drilling deep and hard rocks (such as quartz sandstone, flint, granite, hard limestone, basalt, etc.), traditional PDC cutting teeth will face problems such as rapid wear, impact fracture and thermal degradation. Therefore, it is necessary to select PDC products with high wear resistance, high impact resistance and excellent heat resistance.

1. The thickness of the diamond layer: Generally, the diamond layer is about 1.5 to 2.0mm, it wears out quickly. Choose a thicker diamond layer of 2.5mm to 4mm to extend the wear time and service life.

2. Heat resistance. Select PDC cutter with strong heat resistance. ordinary PDC teeth will undergo graphitization above 750°C, leading to rapid wear. The heat resistance of cobalt-removed PDC teeth can be increased to over 1200°C, making them highly suitable for high-temperature hard rock environments.

3. Impact toughness. Select PDC cutter with high impact resistance, use wavy carbide matrix surfaces, enhance the bonding strength between the diamond layer and the cemented carbide matrix, and improve impact resistance.

4. Tooth profile and relief Angle. Conical or bread-shaped teeth are sharper than standard round ones, have better penetration, can break hard rock with lower drilling pressure, and reduce vibration and impact. Select an appropriate relief Angle (typically 15°-25°) to ensure sufficient support strength in hard rock, preventing it from being swallowed too deep and getting stuck or broken.

5. Tooth distribution design and drill bit body type. Hard rock drilling requires a higher tooth density, which can reduce the stress on each tooth and improve the overall stability and service life of the drill bit. For extremely hard and abrasive formations, tire-type PDC bits are usually superior to steel-type bits.

---EDITOR: Doris Hu, Sarah Shi

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]