What is an End Mill?

End mills are one of the most commonly used tools in metal cutting, widely applied in milling, slotting, contouring, and other operations. As a key design parameter, the helix angle directly influences cutting forces, machining quality, tool life, and processing efficiency.

An end mill is a rotating cutting tool with cutting edges (flutes) on both its end face and its periphery. Unlike a drill bit, which primarily cuts axially (straight down), an end mill is designed for lateral (sideways) cutting, plunging (axial cutting into the material like a drill), and contouring. They come in a dizzying array of types, distinguished by:

-Number of Flutes: 2, 3, 4, 5, 6, 8 or more. Affects chip evacuation, surface finish, material removal rate, and tool strength.

-Geometry: Helix angle (affects cutting forces and chip flow), core diameter (affects rigidity), rake angles (positive, neutral, negative - affects cutting aggression and strength).

-Cutting End Shape: Square end, ball nose, corner radius (bull nose), roughing (corncob), tapered, chamfer, drill mills, etc.

-Shank Type: Straight shank, Weldon flat, Capto, HSK, etc.

--Material: High-Speed Steel (HSS), Cobalt Steel (HSS-Co), Solid Carbide (most common for CNC), Indexable Carbide Inserts, Diamond-Coated Carbide, etc.

-Coatings: TiN (Titanium Nitride), TiCN (Titanium Carbonitride), TiAlN (Titanium Aluminum Nitride), AlTiN (Aluminum Titanium Nitride), ZrN (Zirconium Nitride), Diamond-Like Carbon (DLC), etc. Enhance hardness, lubricity, and heat resistance.

The versatility of end mills lies in their ability to perform numerous critical machining operations:

Face Milling (Slab Milling):

Application: Creating large, flat surfaces on the top face of a workpiece.

Tool Choice: Primarily larger diameter end mills (especially square end or corner radius) or dedicated face mills. Multiple flutes (4, 6+) are common for efficient material removal and good surface finish.

Considerations: Rigidity of setup is crucial. Step-over and depth of cut significantly impact surface finish and productivity.

Peripheral Milling (Profile Milling):

Application: Cutting along the outside or inside contour (profile) of a workpiece. This defines the shape.

Tool Choice: Long-reach end mills (often with reduced neck diameters) are needed for deep pockets or walls. Ball nose end mills are essential for complex 3D contours. Corner radius end mills provide strength for profiling corners. Flute count depends on material and desired finish.

Considerations: Tool deflection is a major challenge in deep profiling. Climb vs. conventional milling strategy impacts tool life and surface finish.

Slotting:

Application: Cutting narrow, straight channels or grooves into the workpiece. Can be through-slots or blind slots.

Tool Choice: End mills specifically designed for slotting often have a center-cutting capability (allows plunging) and optimized chip evacuation. 2 or 3-flute end mills are common to provide adequate chip space, especially in softer materials like aluminum. Roughing end mills can be effective for wider slots.

Considerations: Chip evacuation is critical to prevent recutting and tool breakage. Peck milling cycles are often used for deep slots. Tool diameter must match slot width or use trochoidal milling paths for narrower tools.

Pocketing:

Application: Creating enclosed cavities or recesses within the boundaries of a workpiece. Can be shallow or deep, simple rectangular or complex shapes.

Tool Choice: Center-cutting end mills are mandatory (for plunging into the pocket). Roughing end mills excel at quickly removing bulk material. Finishing end mills (ball nose, corner radius, or square end) create the final walls and floor. Long-reach tools needed for deep pockets.

Considerations: Efficient toolpaths (like trochoidal or adaptive clearing) are crucial for productivity and tool life in deep pockets, minimizing tool engagement and heat. Chip evacuation remains paramount.

Plunging:

Application: Axially feeding the end mill straight down into the material, similar to drilling. Used to start pockets, create holes (especially non-standard sizes), or for ramping strategies.

Tool Choice: Center-cutting end mills only (cutting edges extend fully across the end face). 2 or 3-flute designs often perform best. Drill mills are specialized hybrids.

Considerations: Plunging generates significant axial force and heat. Peck cycles and proper coolant/lubrication are essential. Not as efficient as drilling for standard hole sizes.

Ramping:

Application: Moving the end mill both axially (down) and radially (sideways) simultaneously. Used as an efficient way to enter material for pocketing or profiling, or to machine angled surfaces.

Tool Choice: Robust end mills capable of handling combined axial and radial forces. Center-cutting capability is required.

Considerations: Ramp angle and feed rate must be optimized to avoid tool overload and breakage. Creates a smoother entry than plunging.

3D Contouring:

Application: Machining complex, sculpted surfaces with compound curves. Common in molds, dies, aerospace components, and prosthetics.

Tool Choice: Ball nose end mills are the primary tool. The radius of the ball defines the level of detail achievable. Long-reach ball nose mills are needed for deep cavities. Finishing passes require sharp, high-quality tools.

Considerations: Requires sophisticated CAM programming. Step-over distance directly impacts surface finish and machining time. Tool deflection at the tip of long ball nose mills is a critical concern.

Chamfering and Deburring:

Application: Adding beveled edges (chamfers) to break sharp corners or removing burrs (rough edges) left by previous operations.

Tool Choice: Dedicated chamfer mills (with angled cutting edges) or standard end mills used at an angle. Specialty deburring tools exist, but corner radius end mills are often effective.

Considerations: Light cuts and appropriate feed rates ensure a clean edge without chattering.

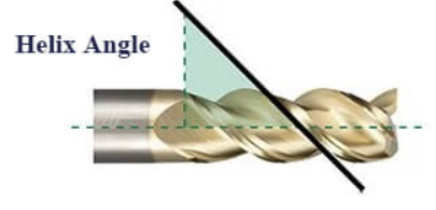

Definition of Helix Angle

The helix angle refers to the angle between the cutting edge helix of an end mill and the tool's axis.

Based on the angle, the helix angles of end-mills can be classified as follows:

Small helix angle (10° - 30°): It is suitable for the rough machining of high-rigidity materials. Although the cutting force is relatively large, the chip evacuation performance is poor.

Medium helix angle (30° - 45°): It applies to most materials, balancing the cutting force and chip evacuation performance.

Large helix angle (45° - 60°): It is used for finishing and machining difficult - to - cut materials. The cutting force is small, and the chips can be evacuated smoothly.

Impact on Machining

1. Cutting Force

Cutting force is one of the most crucial factors in the machining process. As the helix angle increases, the radial cutting force decreases. This is because an end - mill with a larger helix angle cuts into the workpiece more smoothly, reducing impact and vibration. For workpieces with insufficient rigidity, this can effectively reduce deformation and vibration.

However, when the helix angle increases, the axial cutting force increases. The machine tool spindle and fixture need to have sufficient axial rigidity to withstand this force. Therefore, when choosing an end - mill with a large helix angle, it is necessary to ensure that the machine tool has enough rigidity.

2. Chip Evacuation

The helical flutes of the end mill provide a natural channel for chip evacuation. The larger the helix angle, the easier it is to expel chips. This is also beneficial for preventing long chips from accumulating and tangling in the flutes, especially during machining with a large feed rate or in deep - slot machining.

An appropriate helix angle can make the chips form into short - curled chips or “9”-shaped chips, which are easier to discharge. This not only improves the machining efficiency but also reduces tool damage caused by chip accumulation.

3. Surface Quality

A larger helix angle can effectively suppress chatter by significantly reducing the fluctuation of radial forces, thus reducing the generation of vibration marks on the machined surface. Meanwhile, the smoothness of the cutting process with a larger helix angle greatly reduces the impact between the tool and the workpiece, making the machined surface smoother and significantly improving the surface quality.

4. Tool Life

An end - mill with a larger helix angle increases the length of the cutting edge that participates in the cutting process simultaneously. This allows the cutting heat and wear to be evenly distributed over a longer cutting edge area, effectively delaying the occurrence of local severe wear and chipping.

Meanwhile, its excellent chip - evacuation ability can quickly carry away the cutting heat, significantly reducing the temperature at the tool tip. This slows down the oxidation and diffusion wear process of the tool material, especially for coated tools, thus extending the tool's service life.

5. Machining Efficiency

The unique helical design of end-mills with large helix angles makes the cutting process more stable. This stability not only enables the tool to operate efficiently at higher cutting speeds but also allows it to withstand a larger feed rate due to a more even distribution of cutting forces. These two factors work together to significantly improve machining efficiency.

At the same time, the smooth chip evacuation and stable cutting process effectively reduce the downtime caused by chip clogging or unexpected tool damage, further optimizing the overall machining process.

---EDITOR: Doris Hu,Penny Xu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]